- A +

- A

- A -

Motorcycle engine three-dimensional inspection

The motorcycle engine is a machine that ignites the fuel mixture entering the cylinder to convert the thermal energy generated by the combustion into mechanical energy, and transmits the power to the rear wheel of the motorcycle through the transmission mechanism to become the driving force of the vehicle. The motorcycle engine has the advantages of small inertia force, low vibration and low noise. The engine plays an important role and has a great influence on motorcycles. Need to grasp the quality problem, the customer wants to scan the data to obtain data, analyze the need for improvement.

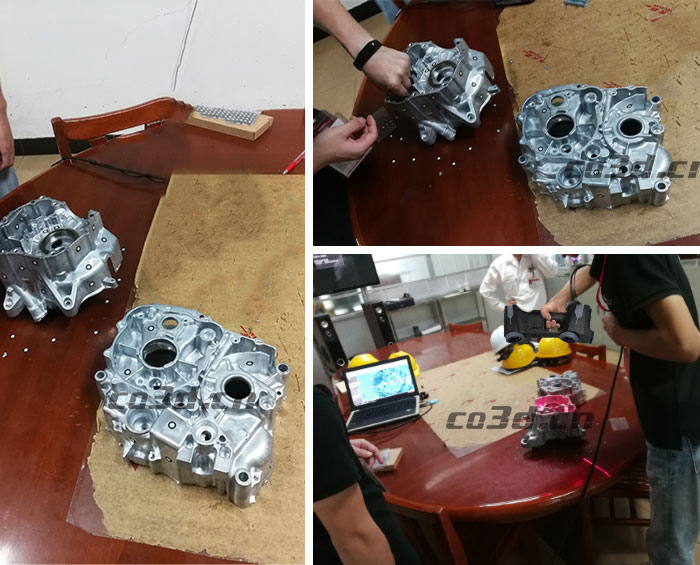

Motorcycle parts real shot map

Practical problems

The overall structure of the power is complex and irregular, the surface is uneven, and the shape of the concave and convex parts is different. The surface has a large number of contour holes, and the size is different, and some are particularly small. The overall structure brings some difficulty to the scanning work.

If the traditional 3D scanner is used, the scanning process will encounter difficulties, the scanning speed is slow, and the details of the deep hole are not scanned properly, resulting in low accuracy of the overall scanning data, which cannot solve the problem and provide a good solution.

Motorcycle parts scanning site map

Co3d solutions

According to the problems we have learned, our engineers use the handheld 3D scanner HOLON760 to quickly scan the high-precision 3D data of the motorcycle engine. The equipment source 7 sets of crossed laser lines plus an additional laser line totals 15 laser lines, and the scanning speed is extremely high. Fast, strong capture and stability. It can also be switched to a single laser scanning mode, which is suitable for scanning deep holes and dead angles. It can solve the problem that the workpiece has many holes and different sizes, and the detail scanning effect is good. The data obtained by this method has high precision and greatly improves work efficiency.

Motorcycle accessories STL data chart

The scanned 3D data is imported into the 3D inspection software to quickly acquire the engine 3D inspection data, which can be compared with the original digital model to generate an intuitive and easy-to-understand detection graphic report to show the difference between the two. The device is easy to operate and short in time, the overall scanning speed is very fast, and the data is complete, the precision is high, the scanning effect in the detail is good, and the scanning process is also very satisfactory to the customer. It solves the problems well and provides complete and reliable data, which is of great help to the later stage.

Motorcycle accessories STL data chart

Motorcycle accessories 3D data map

Motorcycle accessories 3D data map