- A +

- A

- A -

The piston is the 'heart' of the engine of the car. It is subject to alternating mechanical and thermal loads and is one of the most critical parts of the engine. The function of the piston is to withstand the gas pressure, and the piston pin is transmitted to the connecting rod to drive the crankshaft to rotate. The top of the piston is also a component of the combustion chamber. When the piston is working in a high temperature environment for a long time, deformation and accelerated wear will occur, and additional load will be generated. And thermal stress, while being chemically corroded by gas. Due to the important role of the piston in the engine, coupled with the reduction of the surface area, it is not conducive to heat dissipation. In order to ensure that the piston is not melted and properly lubricated, there must be great changes and improvements in design and manufacture, so as to meet the reality of society. Required emission standards.

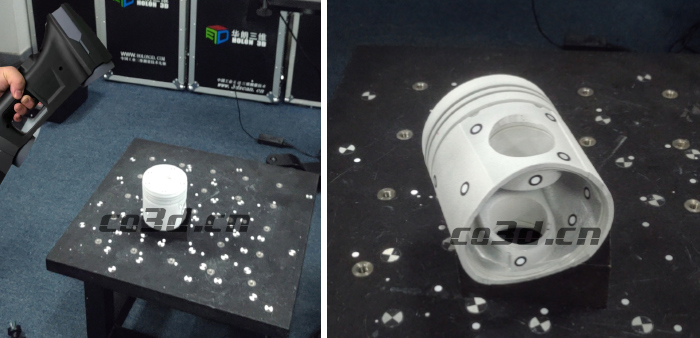

Engine site scan

Practical problems

The piston is composed of four parts, the cylindrical shape is small, and the surface has a ring groove. The protrusion is uneven, and the three sides have holes. The holes on the side are connected, which may cause the scanning to be incomplete. The bottom is hollow. The structure inside is complicated and uneven, and there will be unevenness in the surrounding area.

Overall, although the piston is small in size, the surface structure is very complicated, which brings difficulty to the scanning work. If you use the previous general scanner, the difficulty of scanning will become very large, and the data obtained by scanning will not be comprehensive and will not meet the needs of customers. Need to use the scanners that have been upgraded in all aspects of technological innovation.

Engine site scan

Holon solutions

Using the latest handheld HOLON760 scanner, the light source is 7 sets of crossed laser lines plus an additional laser line to speed up the scanning speed. It can be switched to a single laser scanning mode, suitable for scanning deep holes and dead angles, making the overall scanning accuracy higher. Scanning pistons are very suitable. It can be visualized in real time and flexible in operation. When scanning complex objects, you can see the operations performed on the screen and timely sweep the scans. Use the HOLON760 scanner to scan the piston from different angles and directions. The obtained three-dimensional data is imported into the three-dimensional detection software to perform analysis and analysis with the original data. The data obtained by the scanner is very satisfactory to the customer and is greatly helpful in design and manufacturing.

Engine site scan

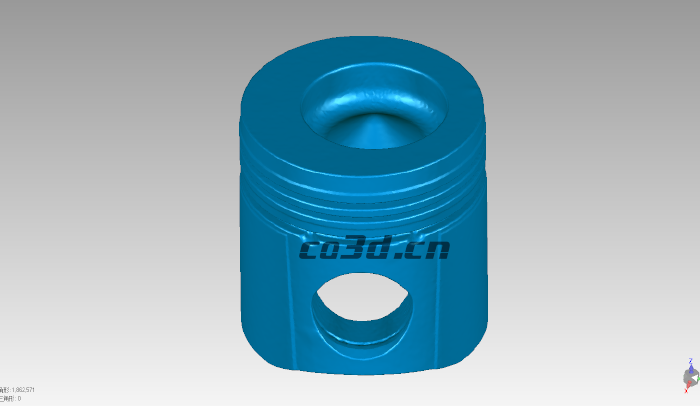

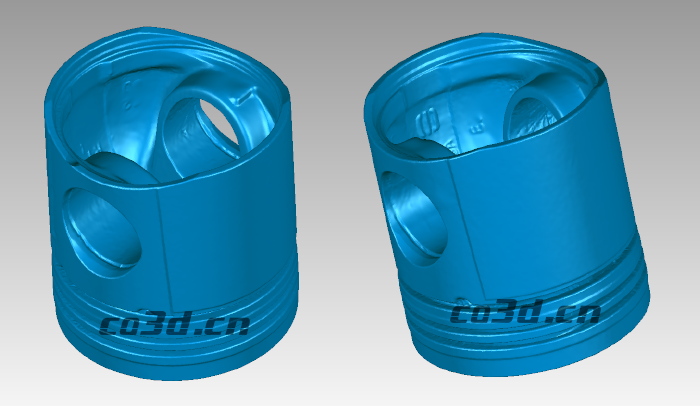

Engine STL data chart

Engine STL data chart