- A +

- A

- A -

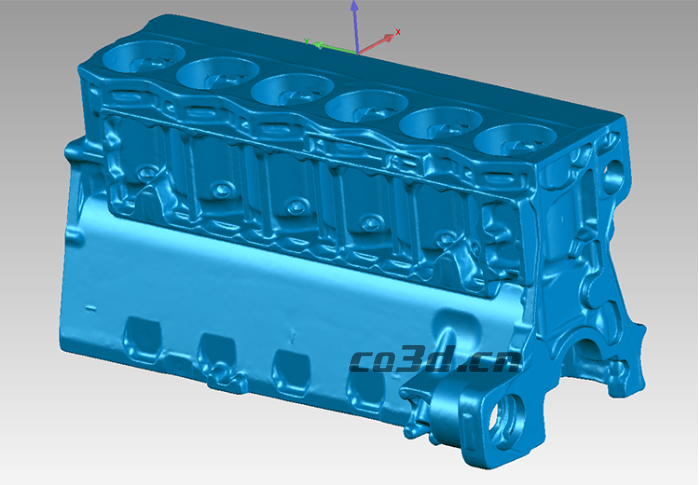

Engine block 3D inspection

The engine is the core that powers a machine. It is the heart of the machine. It affects the power, economy and environmental protection of the machine. It is a very core component. Therefore, the design of the machine is not as good as it is better to have a good engine. Whether in design, manufacturing, process or performance, control, it is constantly improving. The focus now is not only on the power of a machine, but also on energy consumption, exhaust emissions and the environment. Machine manufacturers are trying to improve the performance of their engines and improve the competitiveness of their products. A manufacturer needs to use a scanner to scan the engine for quality inspection and R&D data analysis.

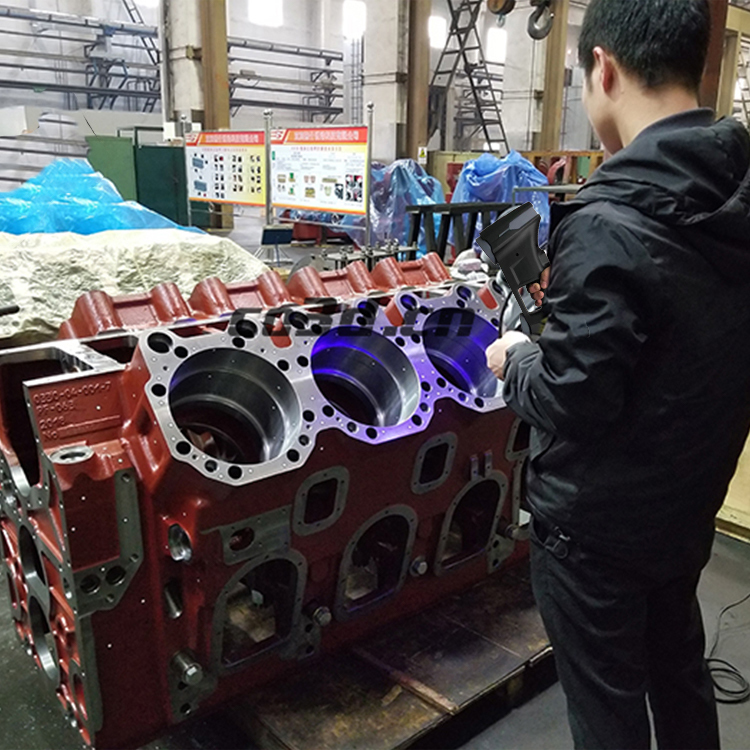

Engine scan

Practical problems

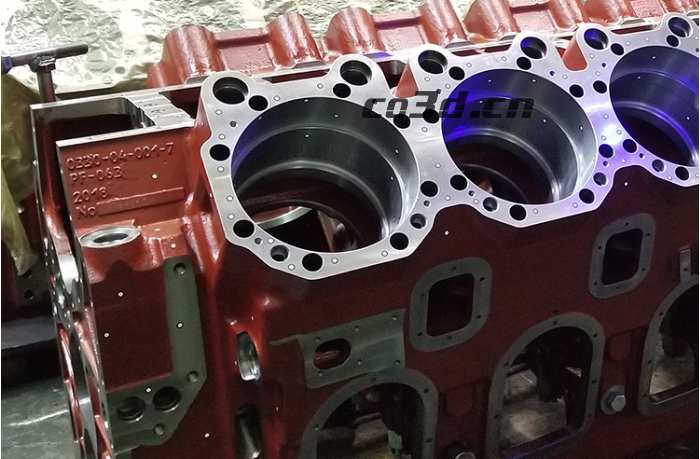

The automobile engine has many system components, large and bulky, and is inconvenient to move. The overall surface is complicated and irregular, the hole position is many, the hole size is different, the hole depth is deep, the scanning difficulty is increased, and the customer requires high precision of scanning data. In the case of a general scanner, for some deep holes, the undulating surface is not easy to capture, the accuracy accuracy is low, and the time and manpower are also excessively consumed, which cannot meet various requirements of the customer.

Engine scan

Co3d solutions

According to the problem of the workpiece, Co3d engineers proposed to use the HOLON760 handheld 3D scanner, 14 1 laser lines to scan the workpiece ultra-fast, can switch a single laser scanning mode, specifically scan the deep hole, the scanning process can be displayed in real time, clearly see the scanning effect And ignore the point to directly fill the sweep, easy to operate, easy to carry, save material. High scanning accuracy makes it easy to scan large and medium-sized objects. After watching the scanning process and scanning out the data, the customer feels that it is suitable for their operation, meets the requirements, and the scanning effect is very good.

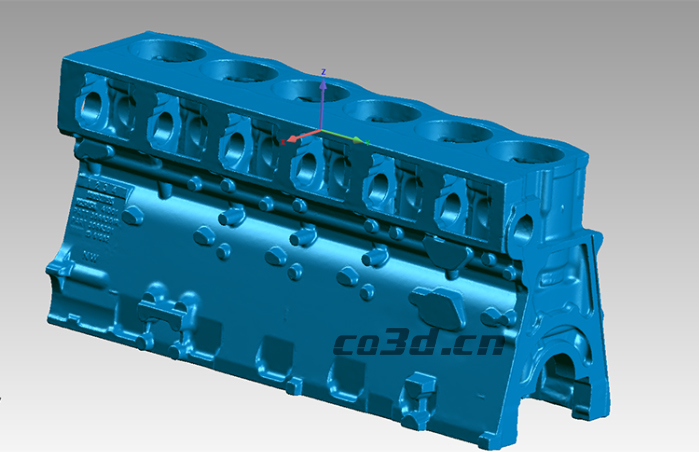

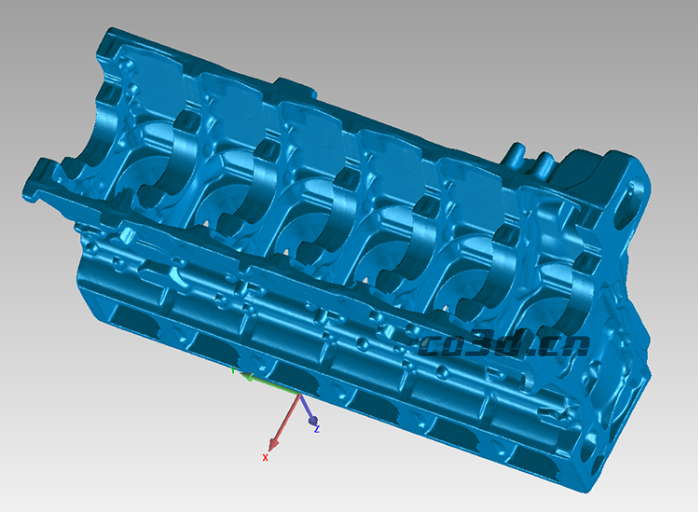

Engine STL data chart

Engine STL data chart

Engine STL data chart