- A +

- A

- A -

With the rapid advancement of technology, there are more and more means of transportation, and ships are one of the important means of transportation, so every component of ship construction is of utmost importance. In ships, there are usually four pistons, and the piston is one of the important components composed of a cast iron skirt and a heat-resistant steel head, which are tightly connected to the piston rod through bolts. The grooves and locating pins on the piston head ensure precise positioning between the components.

Physical picture of ship piston on site

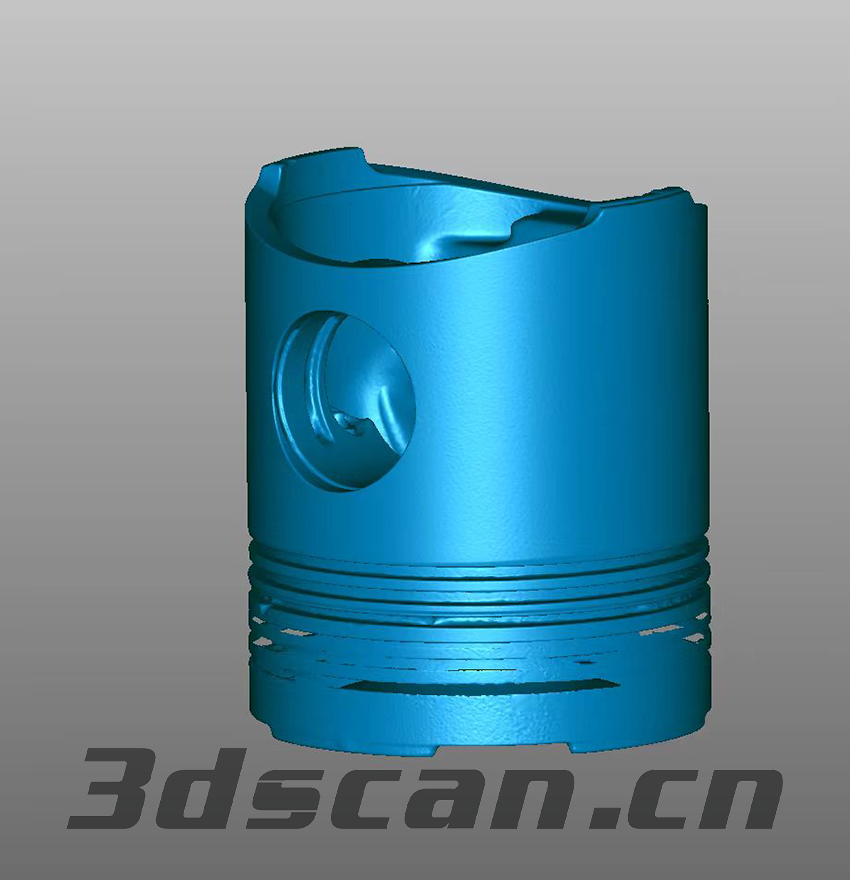

The piston has an irregular cylindrical shape and a surface with ring grooves, which are prominent and uneven. There are holes on all three sides, and the holes on the side are connected, which can easily lead to incomplete scanning; The bottom is hollowed out, with a complex and uneven structure inside, and there may be unevenness around the edges.

If traditional 3D scanners are used, difficulties will be encountered during the scanning process, such as slow scanning speed, uneven scanning of details and deep holes, resulting in low overall scanning data accuracy, inability to solve the problems faced, and inability to provide a good solution.

Physical picture of ship piston on site

Based on the understanding of the issue, our engineers use Model 49, which has extremely fast scanning speed, strong capture ability, and strong stability. It can also be switched to a single laser scanning mode. The device is easy to operate and takes a short time. The overall scanning speed is very fast, and the data is complete with high accuracy. Effectively solved the problems faced, provided complete and reliable data, and brought great help to the later stage.

Ship piston STL data chart