- A +

- A

- A -

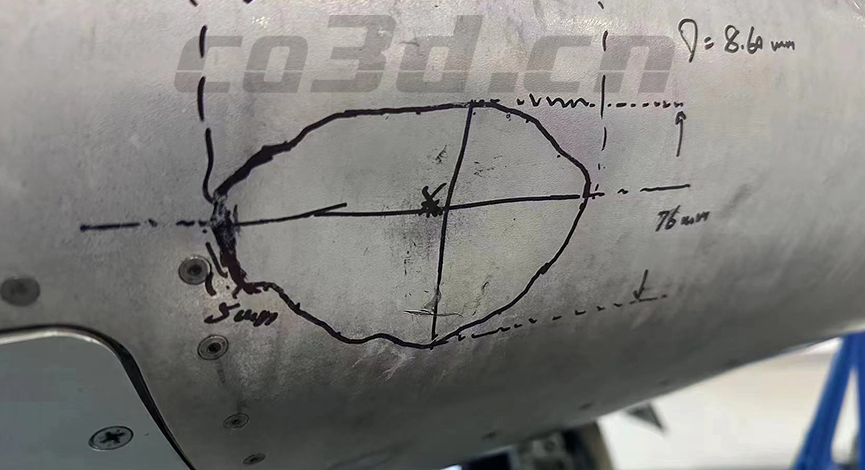

During the long-term high altitude flight of the aircraft, the high intensity air pressure on the shell surface and the objects in the air are prone to produce large range of depressions due to friction and collision. In order to ensure the stability of the cabin air pressure, it is necessary to repair the depressions of the aircraft shell, so as to ensure the safety of the aircraft during flight and achieve the purpose of extending the working time cycle of the aircraft.

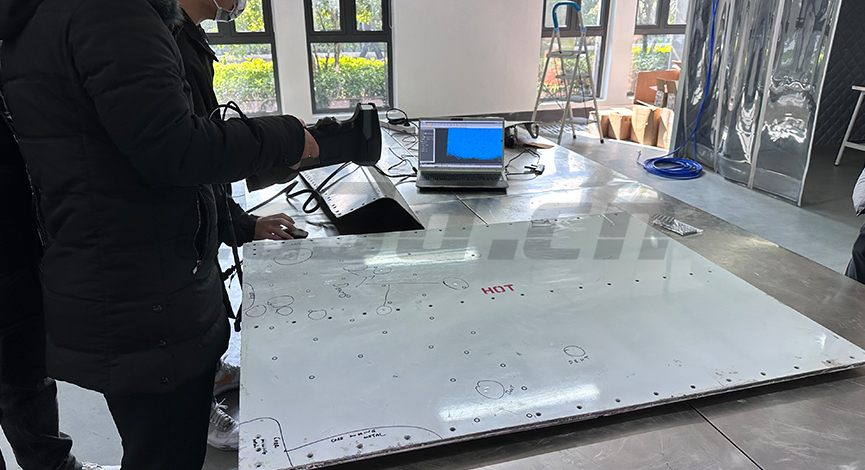

Physical drawing of aircraft site

Physical drawing of aircraft site

Practical problems

After the aircraft was split, in order to quickly achieve the purpose of surface detection, the manufacturer decided to use the Hualang 3D handheld 3D laser scanner HOLON B71 to detect the shell depression

High-precision 3D detection process:

·The scanning is smooth and can be obtained at a glance: the new 3D scanning inspection method simplifies the tedious inspection work and can complete a part surface data scanning within 5 minutes (the maximum scanning width of 600 * 550mm is 2020000 times/second)

·High-precision scanning: Multi-mode scanning, better data capture ability of surface fine parts, and more accurate data presentation for subsequent comparative detection. (The maximum accuracy of single amplitude is 0.01mm, and the repetition accuracy is stable)

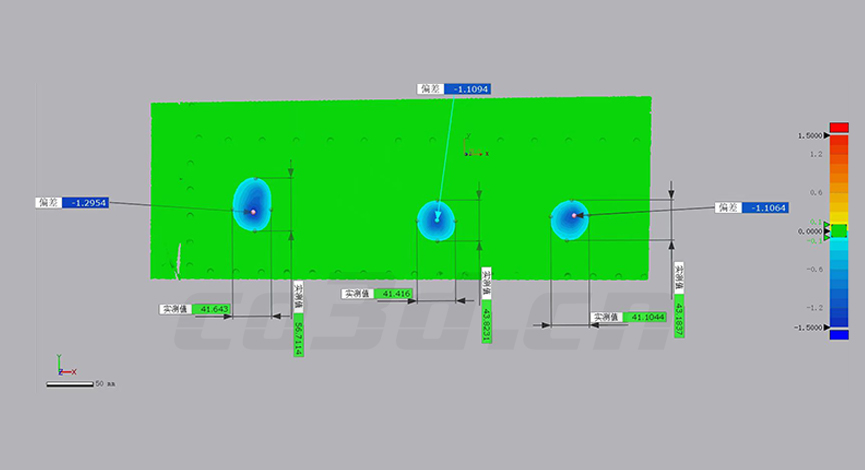

·Simple and easy to understand: import the comparison software, compare with the original digital model, and export the comparison analysis chart with one key. Compare with the real object of the aircraft shell, the surface depression is clear at a glance.

Site drawing of aircraft parts

Depression diagram of aircraft shell

Solutions

After the aircraft was split, in order to quickly achieve the purpose of surface detection, the manufacturer decided to use the Hualang 3D handheld 3D laser scanner HOLON B71 to detect the shell depression

High-precision 3D detection process:

·The scanning is smooth and can be obtained at a glance: the new 3D scanning inspection method simplifies the tedious inspection work and can complete a part surface data scanning within 5 minutes (the maximum scanning width of 600 * 550mm is 2020000 times/second)

·High-precision scanning: Multi-mode scanning, better data capture ability of surface fine parts, and more accurate data presentation for subsequent comparative detection. (The maximum accuracy of single amplitude is 0.01mm, and the repetition accuracy is stable)

·Simple and easy to understand: import the comparison software, compare with the original digital model, and export the comparison analysis chart with one key. Compare with the real object of the aircraft shell, the surface depression is clear at a glance.

Scanning site map of aircraft shell

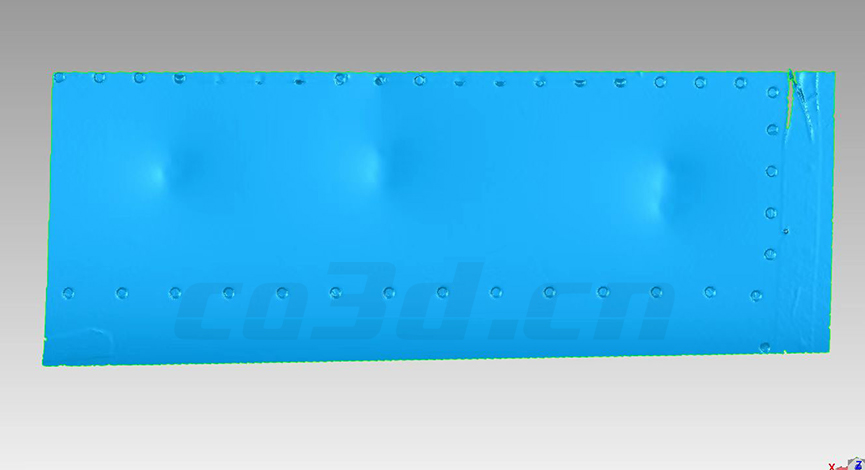

STL data diagram of aircraft shell

Comparative inspection diagram of aircraft shell