- A +

- A

- A -

As a modern kitchen appliance, household dishwashers have gradually entered thousands of households. Not only does it solve the problem of washing dishes at home, but it also improves the quality of life. The structural design of a dishwasher includes interior design, sprinkler system design, water circulation system design, electrical control system design, etc. The inner cavity has good corrosion resistance and durability, and the main materials are stainless steel and ABS resin.

On site physical image of dishwasher chamber

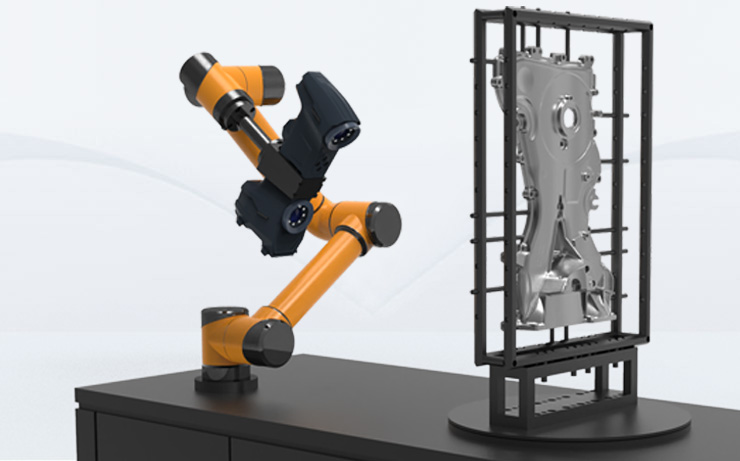

A well-known manufacturer wants to use 3D scanning for 3D scanning and reverse modeling. The workpiece has high reflectivity and uneven internal shape, with various grooves and numerous hole positions. The customer needs to accurately measure the hole positions of the workpiece, which brings great difficulty to traditional measurement work. The use of traditional measurement methods is very cumbersome and time-consuming, which cannot meet customer needs. Customers require fast measurement speed, high accuracy, and no processing of the workpiece, achieving automated 3D measurement, which makes many colleagues hesitant.

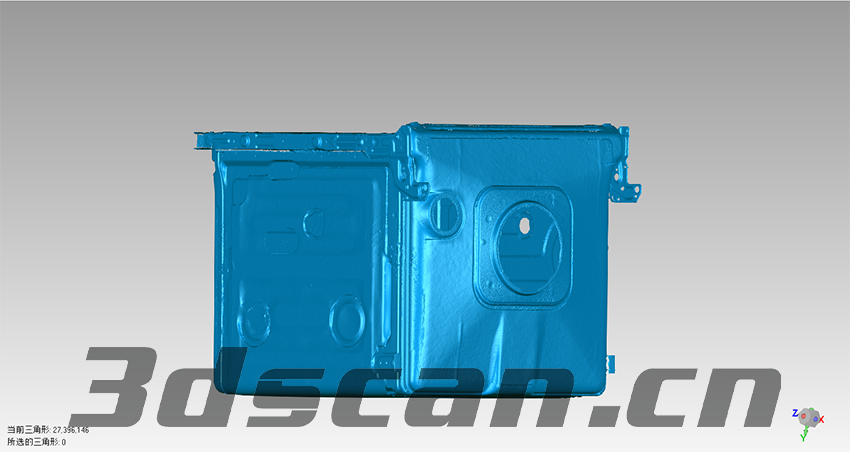

Dishwasher Inner Chamber STL Data Chart

Dishwasher Inner Chamber STL Data Chart

Based on customer needs and workpiece conditions, Hualang 3D technical engineers use Model 49 to scan the workpiece and obtain data. Can reduce the cumulative error of 3D scanning data stitching

1、Preliminary preparation work

Spray developer: improve the contrast of the background color on the surface of the sample and obtain better scanning data

Sticking markers: positioning and splicing the obtained data in scanning software

Comparison data chart of dishwasher chamber

Comparison data chart of dishwasher chamber