- A +

- A

- A -

In

recent years, portable consumer electronics such as smartphones,

tablets, and mobile power sources have emerged in China, driving the

steady growth of small lithium batteries. In addition, electric vehicle

technology is becoming increasingly perfect, and the market demand for

large lithium batteries is gradually releasing. It is expected that in

the coming years, these demand drivers will still exist, and lithium

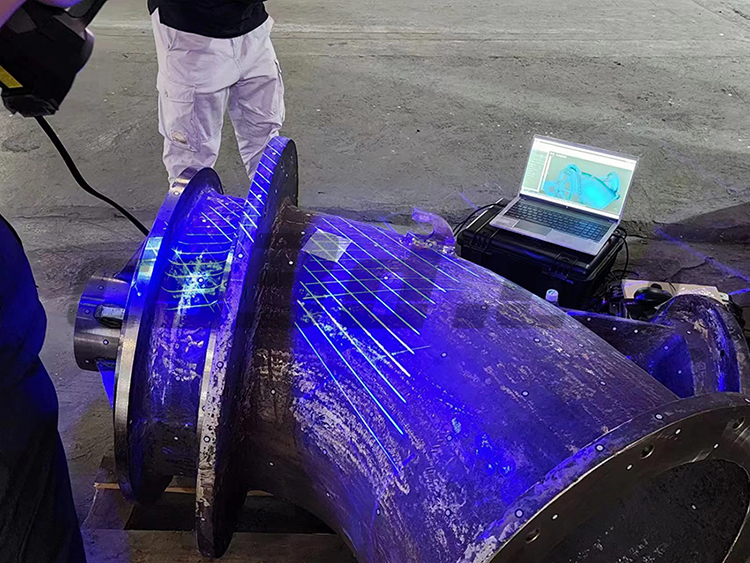

batteries will maintain a growth trend. Scan physical images of the scene

Practical problem

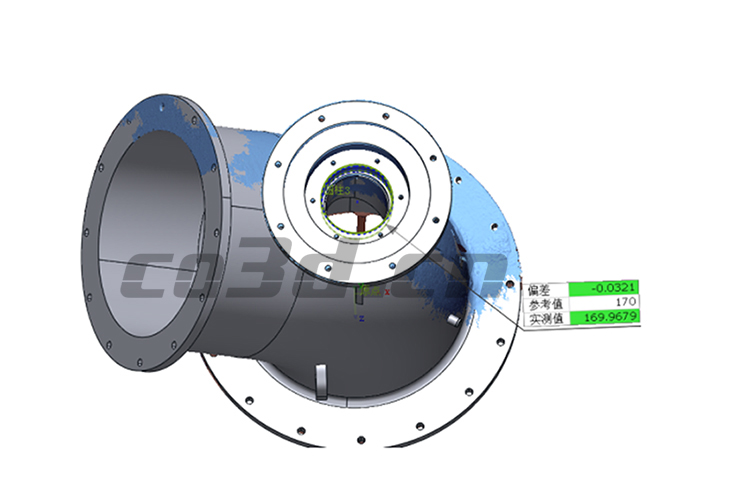

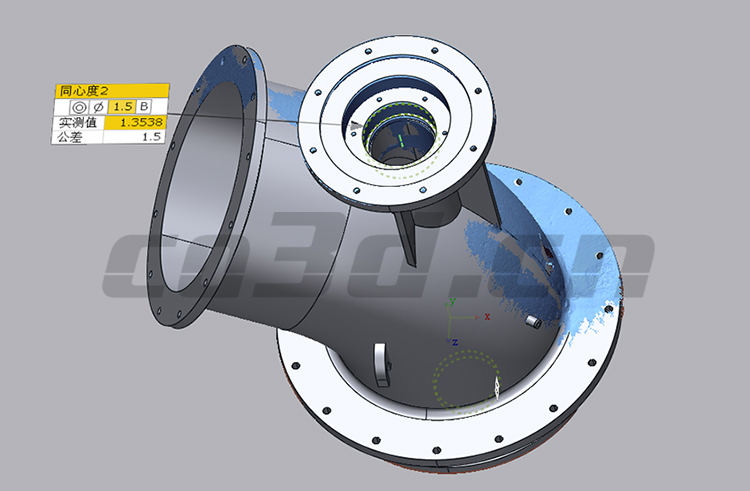

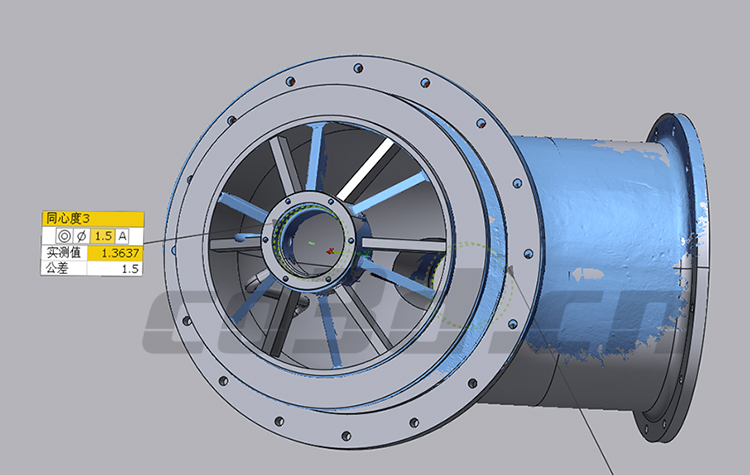

It is necessary to measure the three-dimensional data of lithium battery machined parts and check whether the concentricity data is qualified. The product has irregular shape and large volume, and traditional measurement methods are not accurate enough and time-consuming.

Scan physical images of the scene

Holon solutions

Facing the scanning problem, Hualang 3D engineers use the handheld 3D scanner HOLON DB1, which is flexible and convenient to use and operate, and suitable for various complex application scenarios. With 49 blue laser lines, the scanning speed is fast, the accuracy is high, and the stability is stronger. Quickly obtaining 3D data of processed parts has improved efficiency and cost savings for later product processing, meeting the scanning needs of customers.

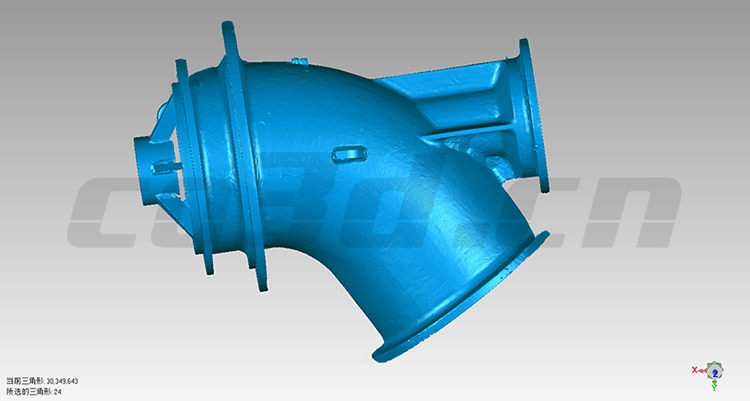

Product STL Data Chart

Data Comparison Figure 1-1

Data Comparison Figure 1-2

Data Comparison Figure 1-3

Data Comparison Figure 1-4