- A +

- A

- A -

With the continuous improvement, many aspects need to be improved. Fans are prone to problems under rated conditions. It is necessary to produce and manufacture fans in strict accordance with product standards. In the later stage, proper maintenance and maintenance are required to improve the service life of the fans. Data detection of the fan.

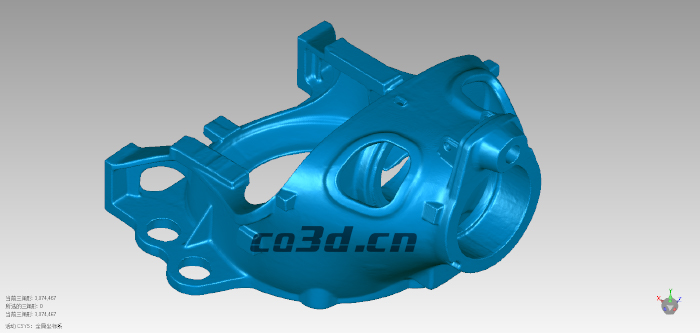

Fan casting real shot map

Practical problems

Fan castings are bulky and cumbersome, unable to move, complex in structure, large in surface variation, uneven bumps around, and deep holes. On the whole, scanning is very difficult.

Using the traditional scanning method and measuring instrument, the internal details of the casting can not be captured clearly, only the outer plane can be scanned, but the large-area scanning is also very time-consuming, slow, and can not meet high efficiency.

Fan casting real shot map

solutions

After understanding the needs and workpieces, the HOLON760 handheld 3D scanner and 3D photogrammetry system (HL-3DP) can acquire high-precision 3D data in a short time, effectively solving the problems such as the cumulative occurrence of scanning measurements.

Fan casting on-site scanning

First, the 3D photogrammetry system HL-3DP will first attach the code point to the object before taking the measurement, and then use the camera to shoot. During the shooting, many different angles of the image will be taken and read into the HOLON3DP software, because each image has a different shooting angle, and each image has a different angle and is triangulated. The HOLON3DP software automatically combines these images and calculates the 3D coordinates of the center of each code point.

Then use HOLON760 handheld 3D scanner to scan, 7 sets of cross laser lines plus an additional laser line for a total of 15 laser lines, can switch a single laser scanning mode, scan deep holes and dead angles, mark point automatic stitching technology and independent research and development scanning software With the ultra-high scanning accuracy and working efficiency, the 3D data of the fan can be quickly obtained for analysis and detection.

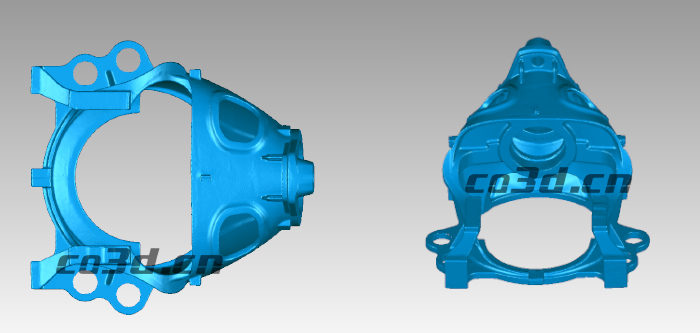

Fan casting STL data chart

Fan casting STL data chart

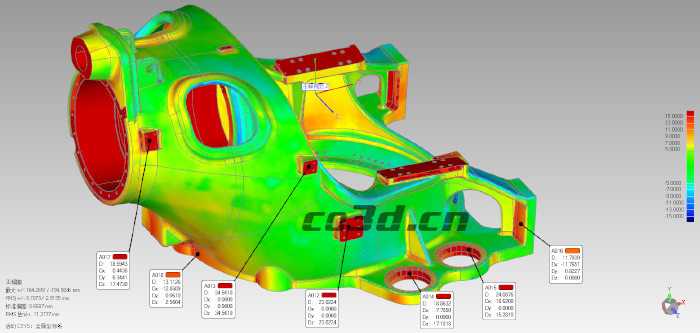

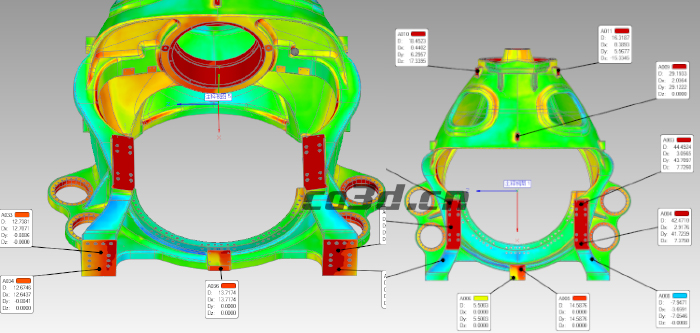

Comparative analysis of three-dimensional inspection of wind turbine castings

Comparative analysis of three-dimensional inspection of wind turbine castings