- A +

- A

- A -

The die surface curvature of the turbine blade is large, the design process is complex, the die precision of the turbine blade directly affects the production of the blade is qualified, the turbine blade mold must be detected and analyzed.

Practical problems

1 the forging process of turbine blade is complex, the design cycle is long, the design task is heavy, so it is necessary to reduce the design strength and speed up the development of turbine blade.

2 turbine blade forging process, the geometric size of large, serious distortion, the need for timely measurement of turbine blade mold.

solutions

Case profile:

A large domestic turbine production enterprises, in order to solve the measurement problem of turbine blade mold, decided to use 3D scanner three-dimensional detection of Huaguang turbine blade mold, by contrast test report, two design of blade mould.

Scanning device:

Huaguang HL-3DS+ 3D scanner

Field of application:

Mold industry, plastic products, small and medium-sized castings, auto parts and other application areas.

Product features:

The portable design: hardware system of small size, less area, no noise, easy assembly and disassembly, convenient to measure the scene

The scanning speed: less than 3-5 seconds can get millions of data points, high efficiency (can also be customized according to customer demand system)

- high precision: single scan precision can reach 0.01mm, compatible with the photogrammetric system, photography allows faster scanning speed and higher precision, 0.006mm/m.

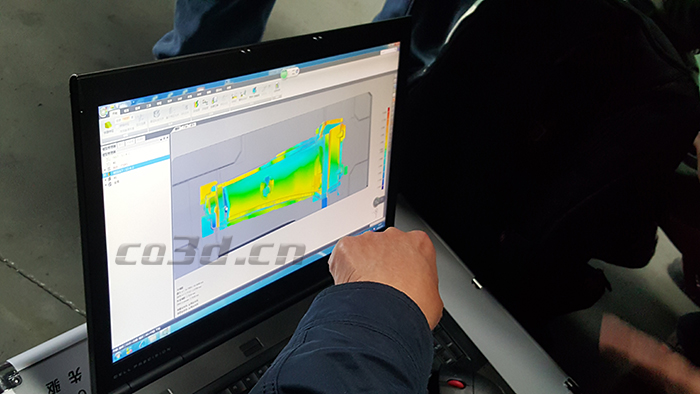

Blade mould scanning spot diagram of steam turbine

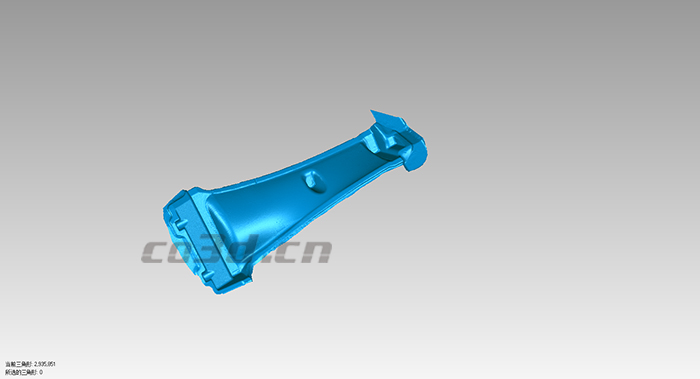

Die scanning STL data of steam turbine blade

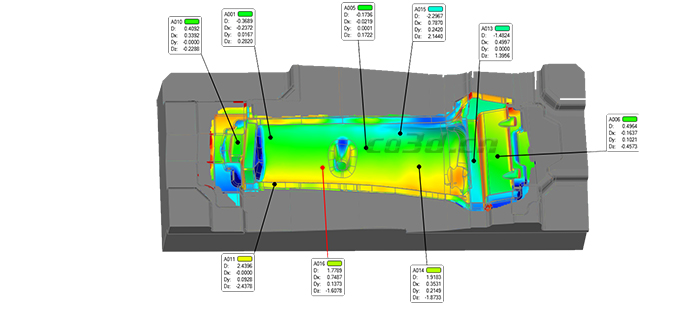

Comparative analysis of steam turbine blade

Three dimensional measurement of die for steam turbine blade