- A +

- A

- A -

Mold manufacturing is a manufacturing process with a long cycle and complex procedures, which involves a large number of repeated measurements and modifications. Therefore, production efficiency has become a recognized and prominent issue in the mold industry. How to improve production and inspection efficiency is a consistent goal pursued by mold manufacturers.

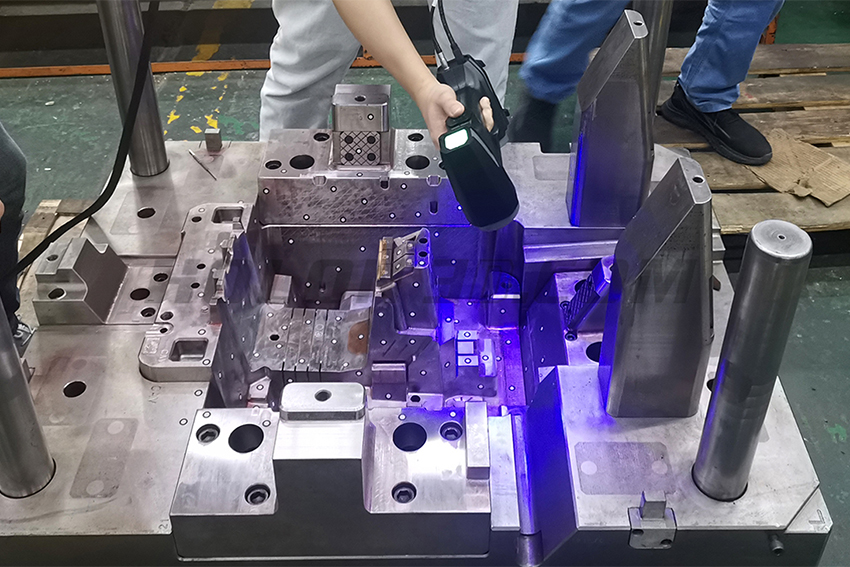

Automobile mold production site picture

Automobile mold production site picture

Automobile molds are characterized by large size, heavy weight, and complex shapes. As molds become more and more sophisticated, the accuracy requirements for mold measurement are also getting higher and higher. In view of the processing and measurement problems in automobile mold manufacturing, micrometers and three-dimensional Traditional detection methods such as coordinates are mostly used in the detection of feature parts. For large-volume automobile molds, the detection cycle is long and the accuracy is unstable in obtaining complete curved surfaces and complex contours. The handheld 3D scanner, through non-contact measurement methods, can perfectly reproduce surface features while also having the function of fast scanning.

Automotive mold scanning site picture

Automotive mold scanning site picture

For the problem of mold scanning, HOLON3D uses the handheld 3D scanner Model 29. It first scans its landmark points to obtain the global three-dimensional coordinate positioning, and then uses the splicing between the laser and the landmark points to obtain the overall three-dimensional data. Then use the comparison software to quickly export the inspection report chart, and the mold detailed data errors can be seen at a glance.

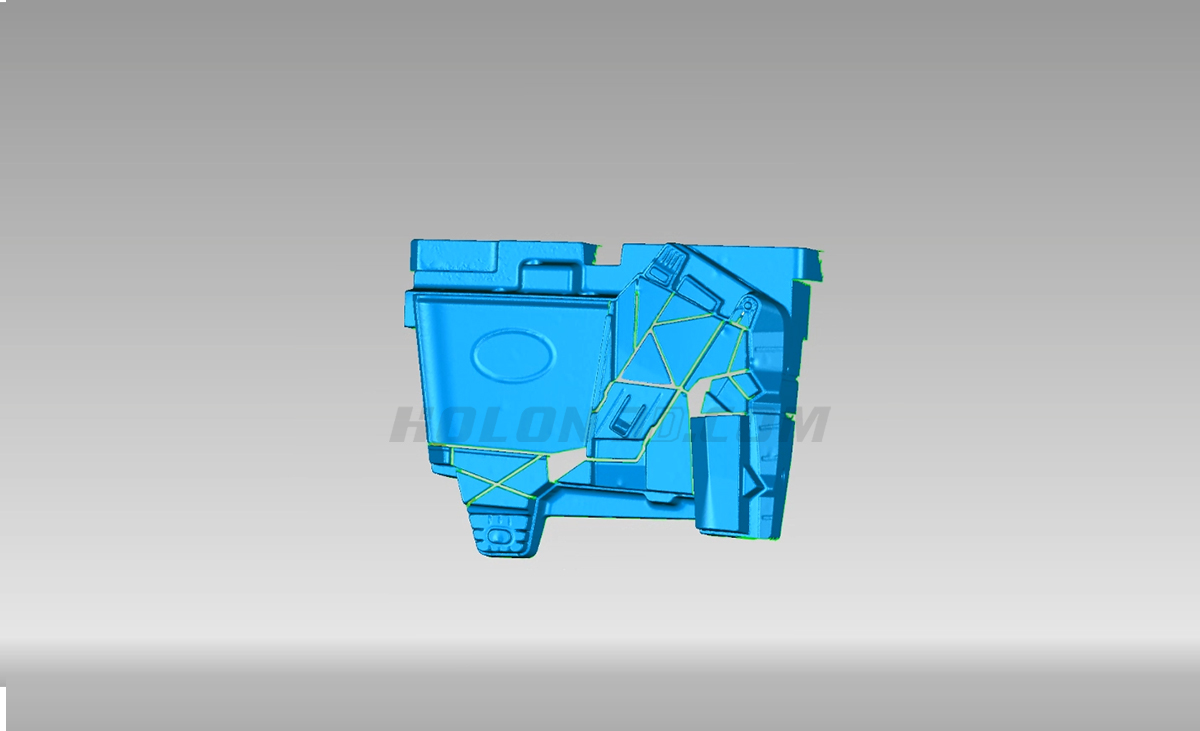

Automobile mold STL data chart

Automotive mold comparison inspection chart

This time, the new three-dimensional measurement of the mold was used to detect the mold, which greatly saved time and cost, provided high-quality guarantee for the customer's subsequent production, and helped the customer quickly and comprehensively solve the difficulties in mold measurement.