- A +

- A

- A -

Mold manufacturing is a long cycle and complex process manufacturing process, which involves a lot of repeated measurement and repair work. Therefore, production efficiency has become a recognized outstanding problem in the mold industry. In the face of increasingly fierce market competition, how to improve the production inspection efficiency is the consistent goal pursued by mold manufacturers

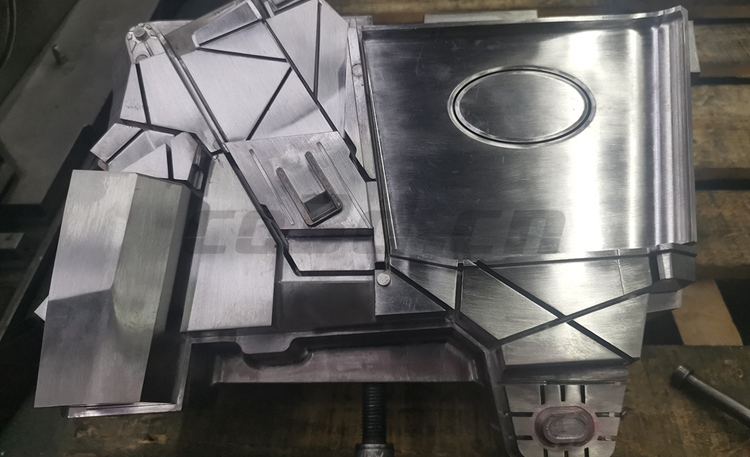

Site Drawing of Automobile Mold Manufacturing

Field drawing of automobile mould

Practical problems

Automobile die has the characteristics of large size, heavy weight and complex shape and surface. With the increasing precision of die, the requirements for precision of die measurement are becoming higher and higher. For the processing and measurement problems in automobile die manufacturing, traditional detection methods such as micrometer and three coordinates are mostly used in the detection of characteristic parts. For large volume automobile die, The detection cycle is long and the accuracy is not stable in obtaining complete surfaces and complex profiles. The hand-held 3D scanner, through non-contact measurement, perfectly reproduces surface features and simultaneously has the function of fast scanning.

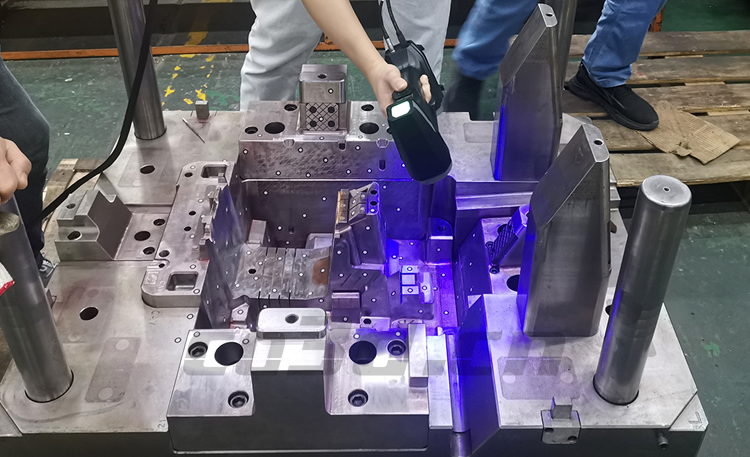

Scanning site map of automobile die

Scanning site map of automobile die

Solutions

For the problem of mold scanning, Hualang uses the hand-held 3D scanner HOLON 771. First, it scans its landmarks to obtain the global 3D coordinate positioning, and then uses the splicing between the laser and the landmarks to obtain the overall 3D data. Then use the comparison software to quickly export the inspection report map, and the error of mold detail data is clear at a glance.

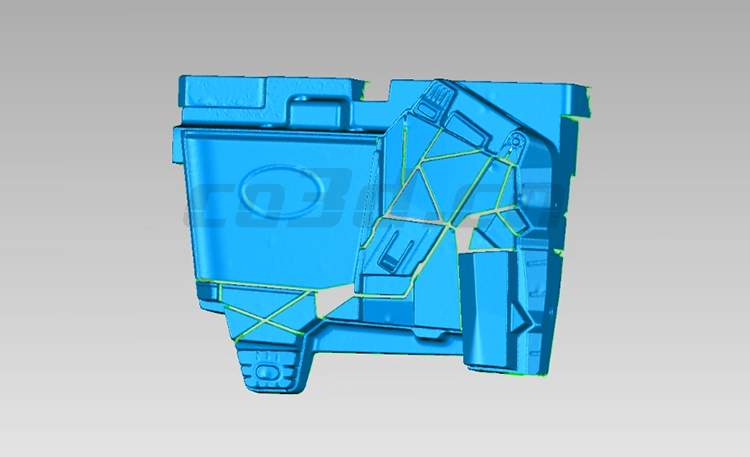

Automobile die STL data diagram

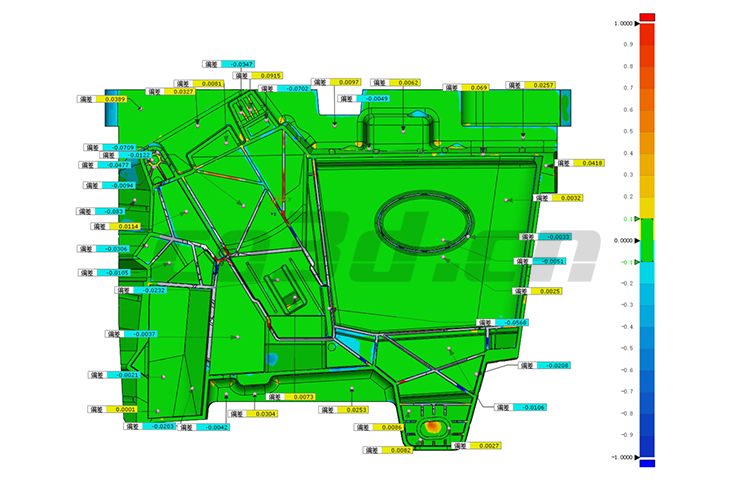

Comparison Inspection Diagram of Automobile Dies

This time, the new 3D measurement was used to detect the mold, which greatly saved time and cost, provided high-quality guarantee for the subsequent production of customers, and helped customers quickly and comprehensively solve the difficulties in mold measurement.