- A +

- A

- A -

A renowned international research institute needs to conduct a comprehensive inspection of the processed nuclear devices and compare them with the digital-analog diagrams of the products, in order to improve the processing technology of nuclear devices and enhance their quality.

Practical problems

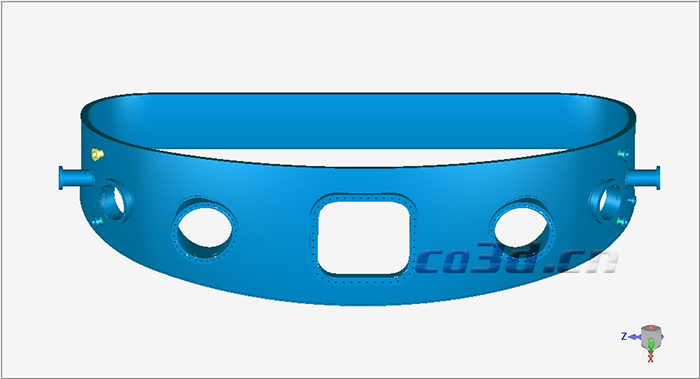

The nuclear device components feature large sizes, complex shapes, and numerous holes, necessitating high precision in the acquisition of three-dimensional data.

Traditional measurement methods suffer from insufficient data acquisition density (insufficient data volume), making it impossible to measure the curved surfaces and arcs of the nuclear device. This results in an inability to perform normal inspections and hinders the subsequent reverse engineering process of creating drawings. The workload is heavy, the efficiency is low, and the accuracy is not high, failing to meet the customer's requirements.

Co3d solution

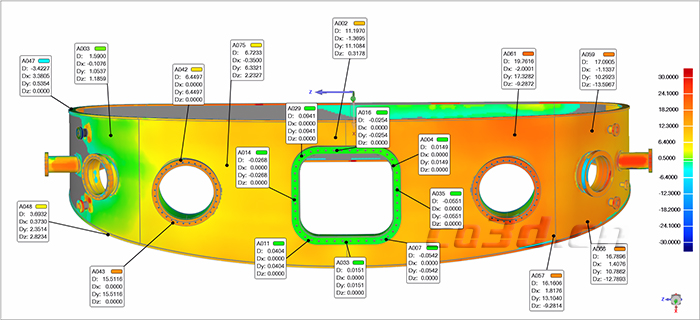

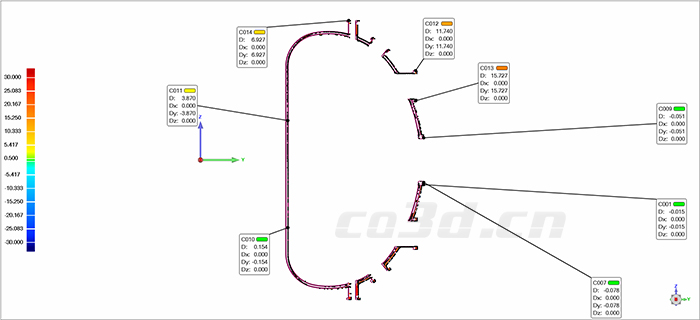

Using a 3D scanner to conduct 3D scanning of nuclear devices, highly accurate 3D data is obtained, ultimately generating detailed inspection reports. Any positional deviations can also be displayed numerically, fully replacing traditional inspection methods.

Preparatory Work

- Spray Imaging Agent: To enhance the contrast of the surface background color of the sample, enabling better scanning data to be acquired.

- Place Markers: These markers allow the acquired data to be positioned and stitched together in scanning software.

3D Scanning

After understanding the specific requirements of the company, the engineers from Huaguang 3D used a combination of the Huaguang 3D scanner 3DW and 3DX to perform the scanning. The 3DW boasts an ultra-large scanning area, making it ideal for scanning large objects. The machine is highly stable, and the entire scanning process only took one hour, achieving an accuracy of 0.05mm. Meanwhile, the 3DX can accurately scan those holes, perfecting the inspection data for the nuclear device.

3D Inspection

By importing the obtained 3D data of the nuclear device into the inspection software, differences between the CAD model of the nuclear device and the manufactured product can be quickly detected. These differences are displayed through intuitive and easy-to-understand graphical comparisons.

The preparatory work for nuclear device scanning

On-site scanning diagram of a nuclear device

STL data diagram of a nuclear device

Comparison inspection diagram of a nuclear device

Nuclear device comparison test chart