- A +

- A

- A -

3D扫描仪技术在不断进步,公司秉承“强调合作、团队精神,强调诚实、自我批评,强调在点滴中改进工作”责任意识、创新精神、敬业精神与团结合作精神是我们企业文化的精髓。实事求是是我们行为的准则。大的财富是那些认真负责和管理有效的员工,力争做三维扫描仪行业的先进厂家。尊重知识、尊重个性、集体奋斗和不迁就有功的员工,是我们事业可持续成长的内在要求。

面临问题

传统的制作方法具有很大的挑战性和随机性,研发过程中周期长、精度低、成本高、复杂性差、产品质量无法得到保证,开模加工和铸造工艺等一系列问题,严重影响产品性能与质量,造成不必要的损失。针对行业所面临的问题,该企业决定引进华朗三维(HOLON3D)三维扫描仪来解决所遇到的难题。

传统的使用方法

1、使用产品样品进行测量、切片,用来绘出模具铸造的参考图纸,从而来加工模具,制作样板,再经经过一道复杂的钳工修整,最后抛光成型;

2、最后在进行试验检测合格后才可投入批量生产,必要时还需通过发动机热机等一些试验,试验不合格需要重新制作样板和修改模具的形状,重新浇铸缸盖进行再次试验。

3、通过选定参考样品的图纸尺寸,结合研制的产品进行恰当修改之后,制成原始模型或直接复制参考样机制作成待修改的原始模型;

4、然后通过实验台进行测试,反复的手工修改偏差尺寸,反复进行试验,直到实验数据达到产品要求,并依此做出阳模,即试验样件;

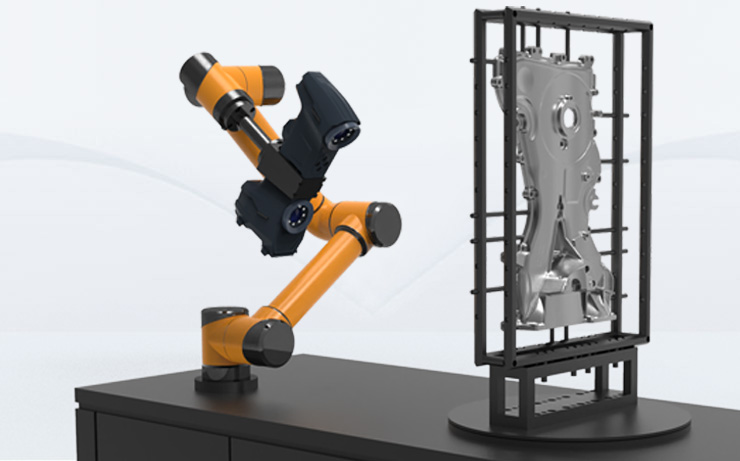

使用华光三维扫描仪的优势

一、操作灵活,可直接在数据上进行修改

二、当需要对模型进行修改时,可直接在模具数据上进行修改,可在短时间内满足客户提出的要求。

三、极大提高现行设备(加工中心等)的可用性

四、通过接受数据服务订单以重建原始模具,提供新的商业机会

五、开发周期缩短:利用三维扫描仪对发动机零件进行扫描,操作简便,直接对物体表面进行高精度数据获取,所得数据与零件实际尺寸相差无几,省去反复试验带来的材料浪费与时间浪费,同时也省去大量测绘,描图的时间。

六、操作方便,省时省力无需繁琐的操作,只需一人就可以将工件进行扫描及建模,省去大量的人力,增加工作效率,间接地节省成本。

采用HOLON3D自主研发的三维扫描仪系列面结构光三维扫描设备,主要用于新型航空发动机产品的研制、各种大型、精密型物件。不仅扫描速度快精度高且稳定性强。操作更加方便快捷,由于该新技术与设备的成功应用,进而加快公司新产品的设计速度,大大降低研发周期和成本。