- A +

- A

- A -

Lijia International Intelligent Equipment Exhibition, founded in 2000, is one of the largest intelligent manufacturing equipment exhibitions in China. It will be held from May 13th to 16th, 2024 at the Chongqing International Expo Center. Hualang 3D will carry high-precision 3D scanners and automated 3D measurement systems with a heavy weight.

The 24th Lijia International Equipment Exhibition in 2024 focuses on cutting-edge manufacturing technologies and showcases the new achievements made in the equipment manufacturing industry in recent years. On the first day of the event, group audiences appeared one after another, and various enterprises gathered everywhere to catch the eye. The avant-garde audience was overwhelmed.

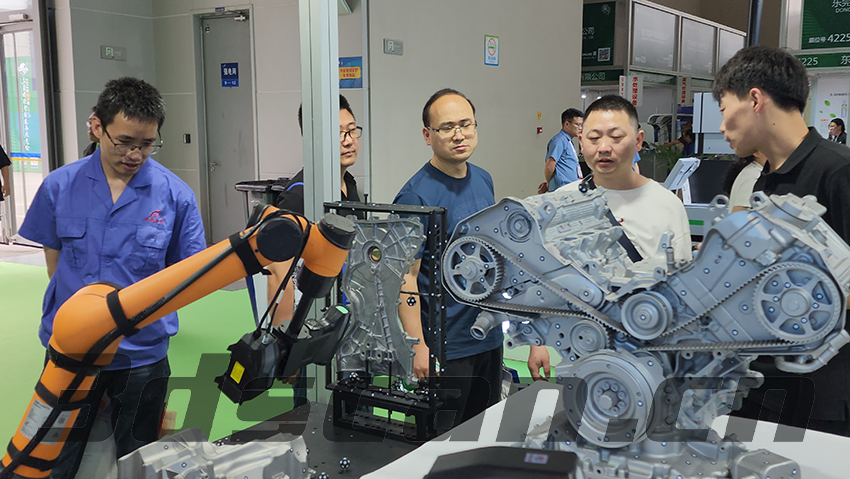

The Hualang 3D high-precision 3D scanner attracted a large number of visitors to stop at the exhibition, and the displayed workpiece V8 engine is highly representative. The Model series scanner has an accuracy of 0.02mm and is easy to operate, making it the best choice in the field of industrial measurement.

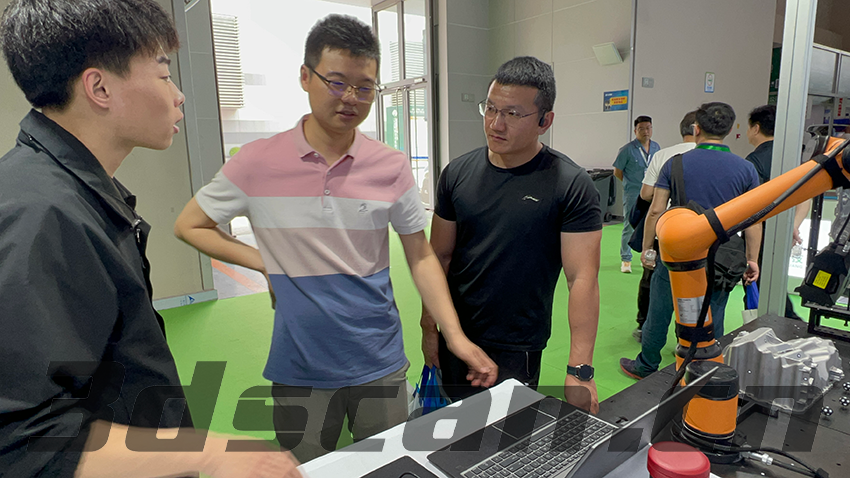

At the exhibition site, engineers showed the audience in detail the four scanning modes of Model 41: wide range mode and standard mode for fast scanning of data; Deep hole mode is used to scan deep holes and dead corners; Ultra fine scanning mode realistically restores fine data sizes. The applicability of on-site audience direct calling is very wide!

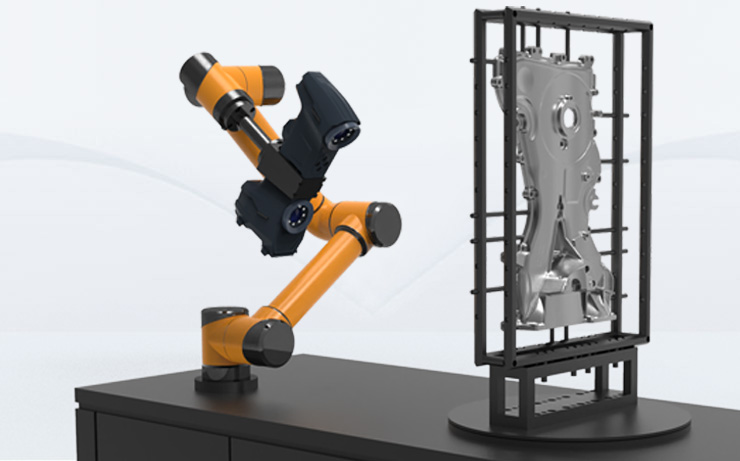

The Hualang 3D automated 3D measurement system Superscan I also attracted attention at the exhibition. It is integrated by a robotic arm equipped with a high-precision industrial grade 3D scanner, with human-machine cooperation, no need for guardrails, and simple and safe operation.

Machines replace manual labor, freeing up manpower, suitable for full-size 3D inspection of production lines, laboratories, quality inspection departments, etc. The on-site audience used their mobile phones to record and take photos, and expressed that compared to traditional measurement methods, this equipment is too advanced!

The engineer showed the customer how to quickly scan automotive sheet metal parts using a small 3D scanner; Miniaturized design, not limited by the on-site environment, flexible and portable, suitable for various working conditions, and able to measure anytime and anywhere. Although the appearance is small, the efficiency is not slow at all!