- A +

- A

- A -

Today, the 3D scanner industry is becoming increasingly mature and is widely used in all walks of life, of course the medical industry is no exception. Medical surgery, orthodontic surgery and other surgeries are crucial events for patients. Failure or other small mistakes will cause discomfort and pain to the patient. The powerful performance of surgical and plastic surgery is a good way to relieve the patient's pain and reduce pressure and weight-bearing. Therefore, the success of the surgical operation has become particularly important.

Starting from the patient's perspective, HOLON3D is committed to the research and exploration of medical repair and pain relief for patients, and has successfully developed various series of software and hardware 3D scanner products to create value for society and mankind.

Dentistry - Dentures

Traditional denture processing is hand-made by technicians based on experience based on the patient's jaw shape. Since the accuracy cannot be guaranteed, the produced dentures will have deviations and will be extremely uncomfortable for the patient. At the same time, the repair process of this method is time-consuming and labor-intensive, the repair rate is high, the production cycle is long, and the accuracy is difficult to guarantee, resulting in poor practical results. Huaguang 3D uses a 3D scanner dental scanning system to obtain the 3D data of teeth accurately, quickly and completely, and combines it with CNC processing equipment to directly produce tooth models, completely improving the traditional tooth repair process and greatly shortening the design and production cycle of dentures. and effectively improve accuracy.

Prosthesis

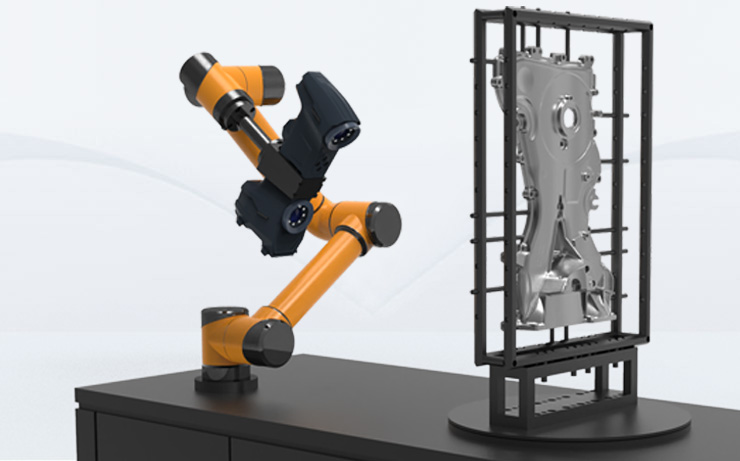

The production of traditional prostheses relies entirely on manual production, and its precision and accuracy are difficult to guarantee. Patients will be very uncomfortable wearing unmatched prostheses, and the production cycle is long, the efficiency is low, and the cost is very high. Hualang 3D uses the HOLON3D 3D scanner to scan and obtain important data such as the shape and girth of the patient's limbs. The prosthetic maker will process and modify the data model according to the data model. After determining the size and shape, the data model will be sent directly for processing. Shorten the production cycle and reduce unnecessary losses during modifications.

Repair and treatment of missing mandible bone

Due to the complex anatomical relationship of the craniofacial region, it is very difficult to determine the scope of jaw bone lesions only through planar images, which also makes it difficult to formulate treatment plans before surgery. By acquiring CT data and using reverse engineering software technology to build a three-dimensional model, the three-dimensional craniofacial anatomy and their relationships can be displayed three-dimensionally and accurately. A three-dimensional digital model of the jaw bone is established based on the patient's jaw bone data. A digital model of the jaw bone defect is established through mirror copy and data interpolation principles. The rapid prototyping machine is then used to create a three-dimensional solid model and an individualized prefabricated restoration model. The prosthesis is connected to the patient's original bone model for trial assembly in vitro, and defects in the design and production of the prosthesis are discovered through in vitro surgical simulation. This method can improve clinical surgical quality and shorten surgical time, and can achieve more precise contour matching of individualized prefabricated restorations.