- A +

- A

- A -

Three-dimensional inspection of automobile tire inner cover

A well-known domestic automotive manufacturer needs to conduct a comparative inspection of the tire inner cover. The inner cover plate is the outer body plate that covers the wheels, which conforms to fluid mechanics, reduces the wind resistance coefficient, and makes the vehicle run more smoothly. The hand-held three-dimensional scanner HOLON B71 independently developed by Hualang 3D is used to conduct three-dimensional scanning of the tire liner, obtaining high-precision three-dimensional data, improving the secondary development efficiency of the tire inner cover, and saving costs, Shorten the development cycle of new products.

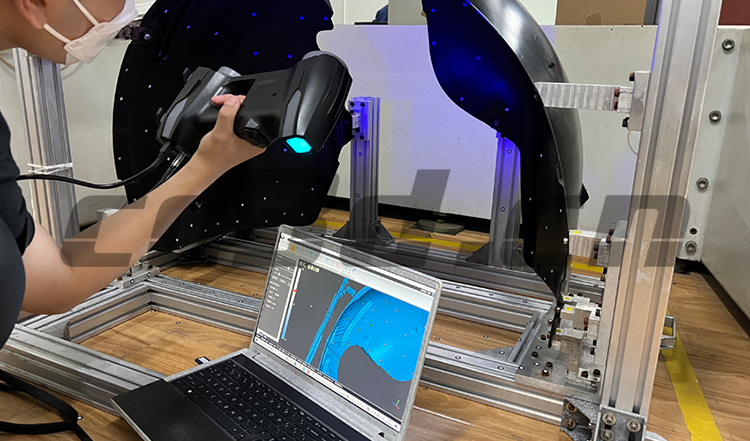

Scanning scene map of automobile tire inner cover

Practical problem

1. Simply using traditional methods (such as gauges, fixtures, and three coordinates) to measure the tire liner is very cumbersome and time-consuming, and it is not easy to accurately and quickly measure and detect the shape of the tire liner.

2. The tire inner liner has a large curved surface, the workpiece is black, and the volume of the tire inner cover is relatively large, which is prone to deformation. It is difficult for ordinary three-dimensional scanners to quickly and accurately obtain a three-dimensional digital model of the automobile bumper.

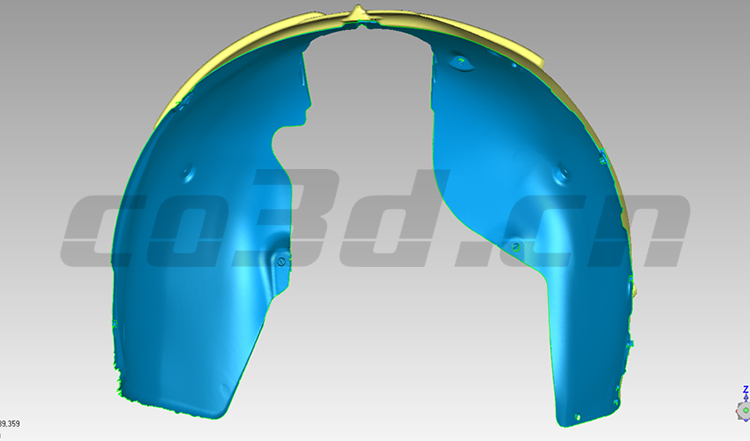

STL data diagram of automobile tire inner cover

Solutions

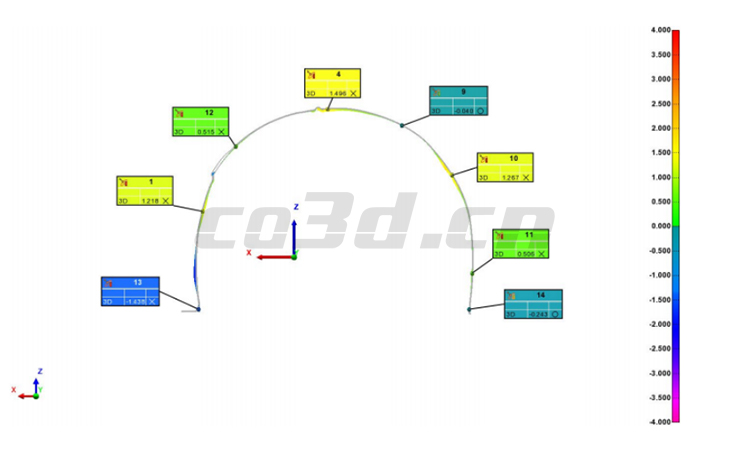

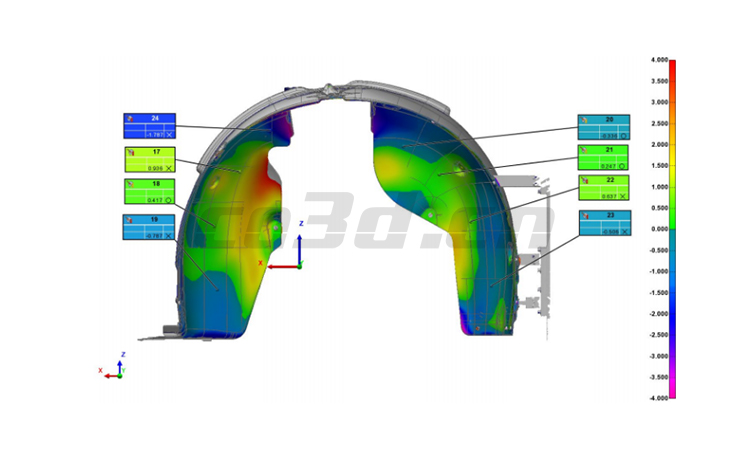

The customer wants to further improve the produced tire inner cover, save production costs, and improve the product qualification rate. Therefore, Hualang 3D engineers have provided a professional solution: use a handheld 3D scanner HOLON B71 (to quickly obtain high-precision 3D data of the tire liner), import a comparison software for 3D data comparison and analysis, and accurately obtain workpiece data errors.

2D sectional analysis diagram of automobile tire inner cover

Comparative Inspection Diagram of Automobile Tire Inner Cover