- A +

- A

- A -

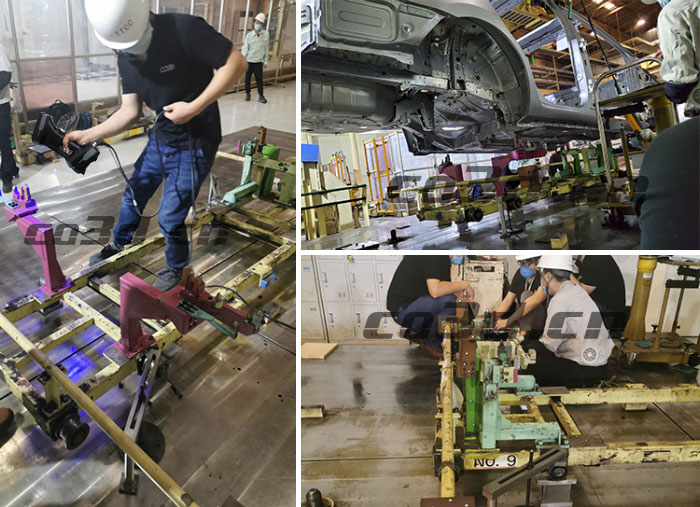

Three-dimensional inspection of automobile inspection mold

The special inspection equipment used by the inspection mold to measure and evaluate the size and quality of the parts, through the online inspection of the parts, thus ensuring the rapid judgment of the quality status of the parts during trial production and start-up production. Therefore, there must be no errors in the dimensions of the inspection mold. Inspection and data comparison are required to avoid errors in the next inspection work and cause trouble for production.

Automobile mold scene scan

Practical problems

The customer has high requirements for the inspection of the inspection mold, the scan data is complete and the error is small, the high data accuracy can clearly reflect the problem, and the speed is fast and the work can be completed efficiently. Using traditional detection methods, the operation is not so convenient, the use time is long, and the measurement data is incomplete, and the included angles and dead angles are not easy to scan out, resulting in low accuracy of the obtained data, and the data cannot be applied to the subsequent work.

Automobile mold scene scan

Co3d solution

The solution proposed by Hualang 3D engineers is to use our handheld 3D scanner HOLON751. The scanner has a fast scanning speed, flexible operation, and can easily scan large and medium-sized objects with a measurement accuracy of up to 0.01mm. It can also visually see the scanning being operated on the screen in real time.

Auto mold STL data chart

Auto mold STL data chart

First, the scanner is used to scan the inspection mold to obtain high-precision three-dimensional data, and the scanning work can be completed in 5 minutes. Then, the post-processing optimization of the acquired data is carried out, and then imported into 3D software for comparative analysis, so as to produce a simple and easy-to-understand analysis report, which is convenient for customers to understand the problem and solve the problem faced by the customer.

Auto mold data inspection chart

Auto mold data inspection chart