- A +

- A

- A -

Auto automatic brake system accessories three-dimensional inspection

A well-known automobile manufacturing company in Guangzhou needs to purchase a set of three-dimensional scanning equipment instead of the traditional measuring method to scan the automotive brake system parts for quality inspection, quickly and accurately obtain detailed three-dimensional testing results, analyze the product's qualification and improve product quality. Accelerate the development of later product development, etc., to save the company's cost and time to improve the company's competitiveness.

Practical problems

Customer background

The customer is a developing US-owned enterprise, introducing German advanced automobile production technology to produce a complete hydraulic base brake system and industrial control valve body. Equipment and manufacturing process technology are at the leading level in China.

Scanned object: 3D inspection of auto brake system accessories

Testing requirements: Detecting the production of auto brake system parts

Recommended solution: Handheld 3D scanner HOLON 760+ 3D inspection software

Handheld 3D scanner HOLON 760

Detection difficulties

Automobile automatic brake system accessories are an important part of the whole car. It not only affects the safety performance of the car driving, but also is one of the guarantees of our life safety. The measured workpiece is small in size and complex in structure, the internal groove shape is different, and the curved surface contour hole There are many bits, and the traditional manual detection can not accurately measure the surface, wall thickness and hole position of the workpiece, and it is time-consuming, labor-intensive and inefficient.

Auto automatic brake system parts site map

CO3D solutions

Due to errors in the production process of auto parts, the traditional measurement methods, the data obtained are limited and can not accurately obtain the three-dimensional data of the auto brake system accessories. The three-dimensional technical engineer: use the handheld 3D scanner HOLON760 to quickly scan the car. The 3D data of the accessory is used for product quality inspection, which is fast, easy to operate and short in time, and the data accuracy is extremely high, successfully solving the problems faced by the customer.

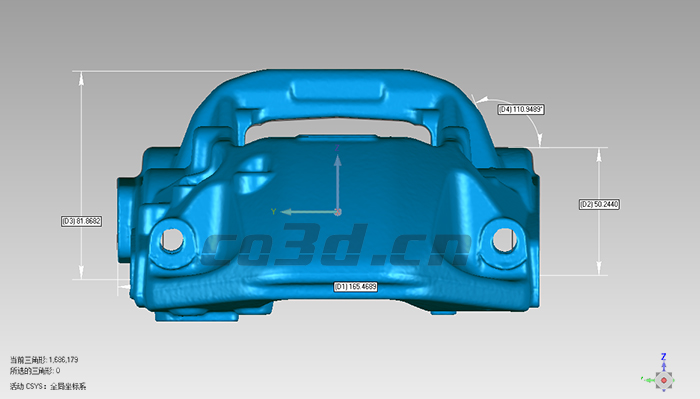

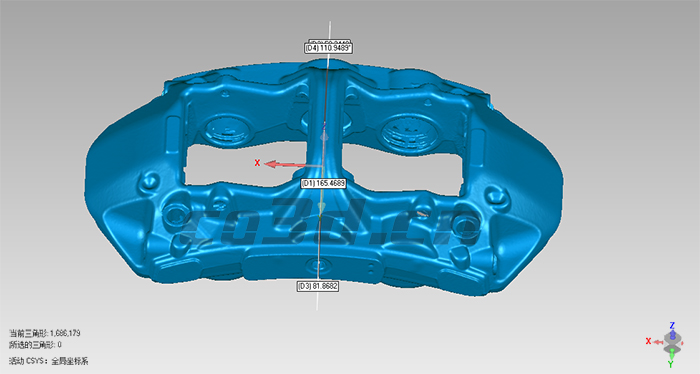

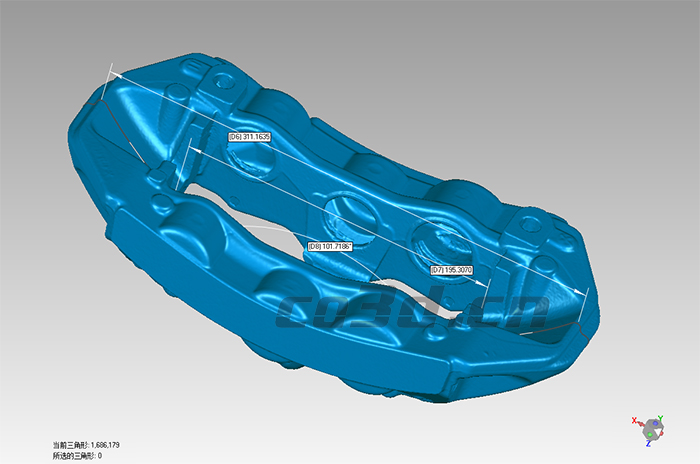

Auto parts STL data chart

Auto parts STL data chart

Auto parts STL data chart

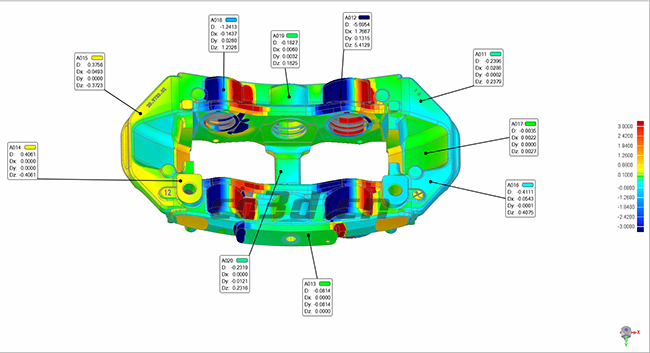

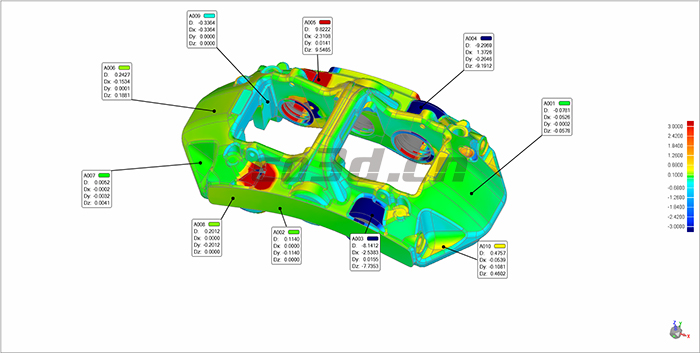

Auto parts 3D inspection analysis chart

Auto parts 3D inspection analysis chart

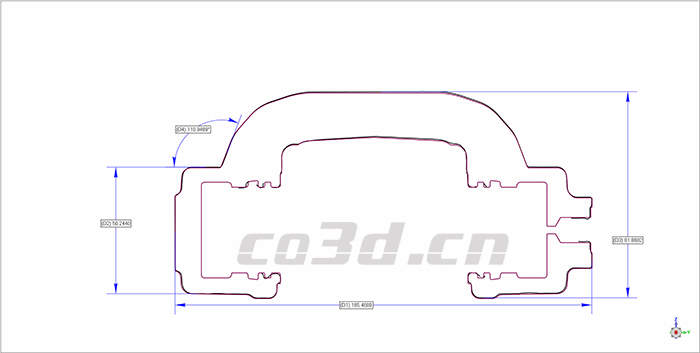

Auto parts cross section analysis comparison chart