- A +

- A

- A -

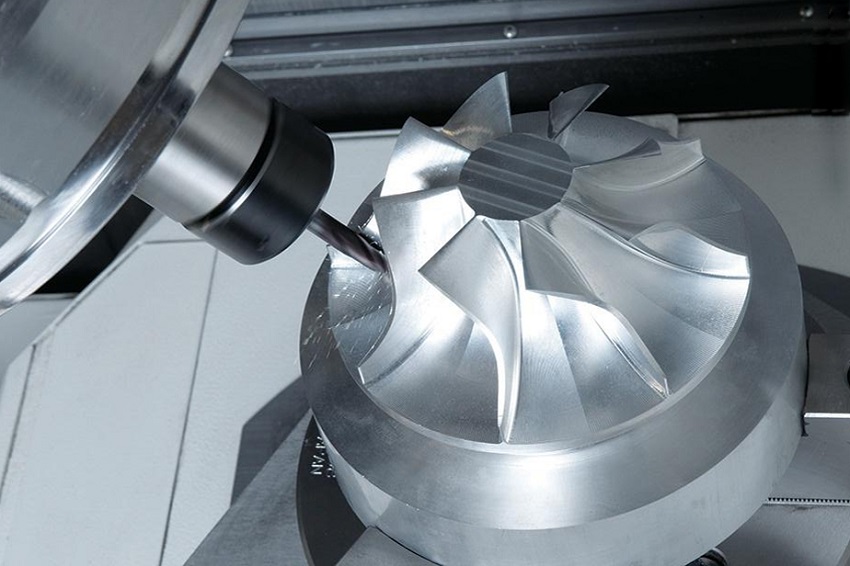

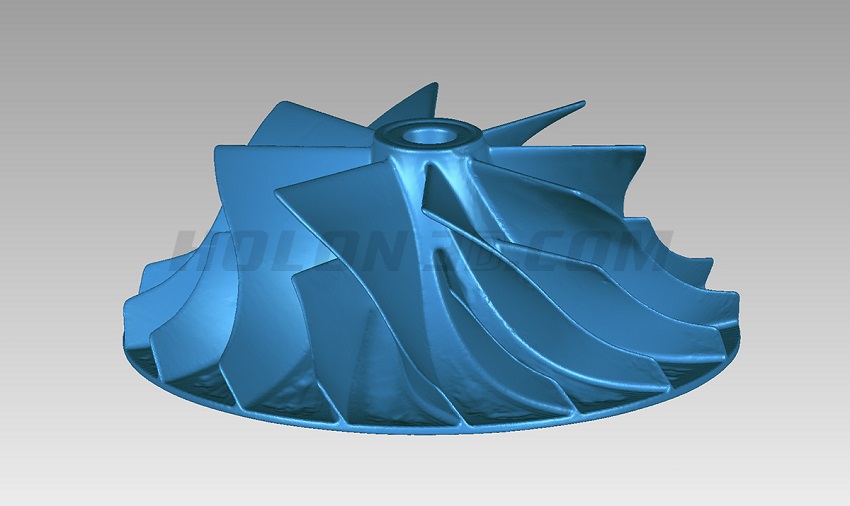

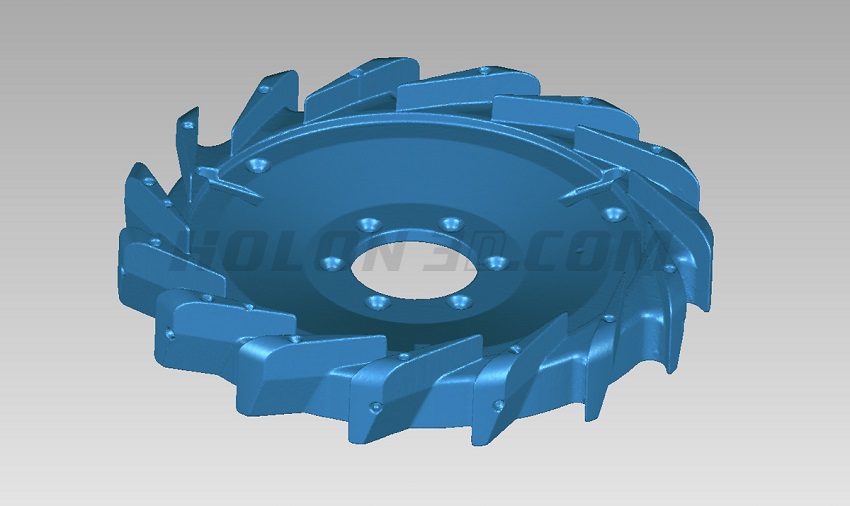

As the core component of the aeroengine, the overall outline of the impeller is a three-dimensional free-form surface. In the inspection of similar parts of impellers, high-precision inspection is the top priority in the entire inspection process. In the process of multiple inspections and practices, a mature and complete inspection plan has gradually been formed.

Aircraft engine site diagram

Aircraft engine site diagram

Aircraft impeller inspection usually requires full-size inspection and requires a lot of inspection items. The traditional single-point inspection is too slow and cannot be applied to the heavy work of multi-part inspection. The surface is seriously distorted and the three-dimensional data of the equipment cannot be maintained during measurement. Stable, at this time there are higher requirements for measurement software algorithms and machine accuracy.

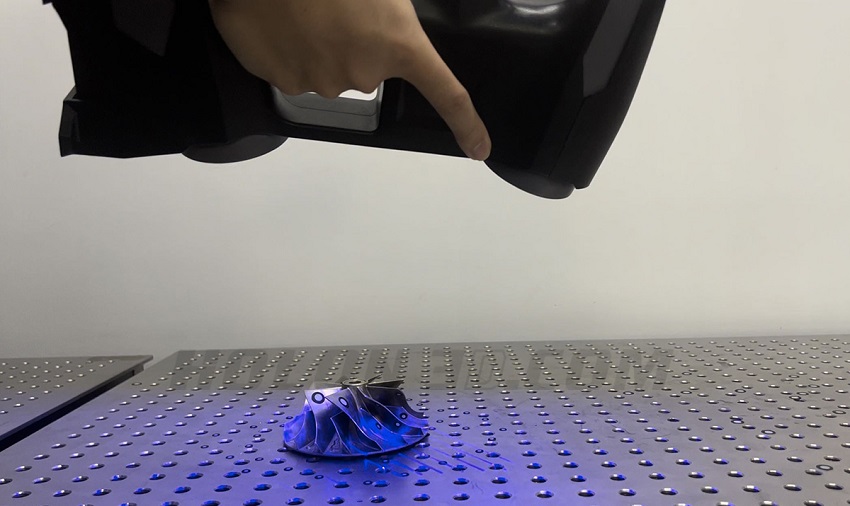

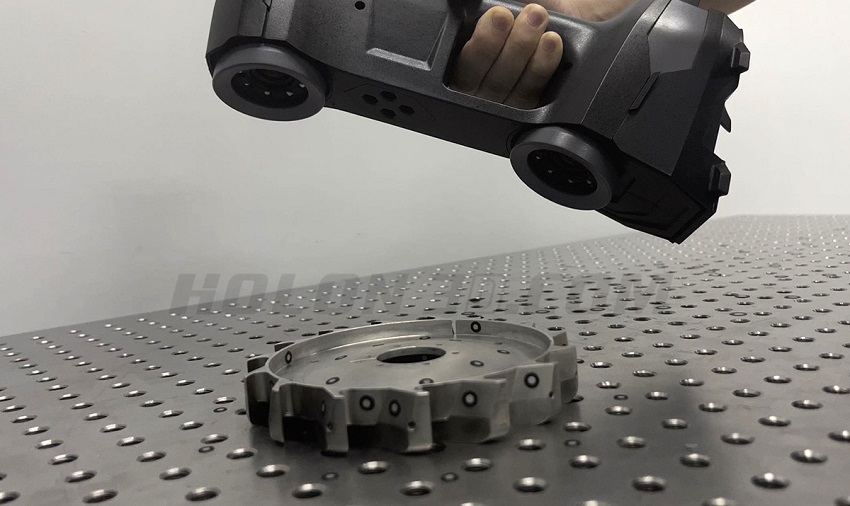

Aircraft impeller scanning site picture

Aircraft impeller scanning site picture

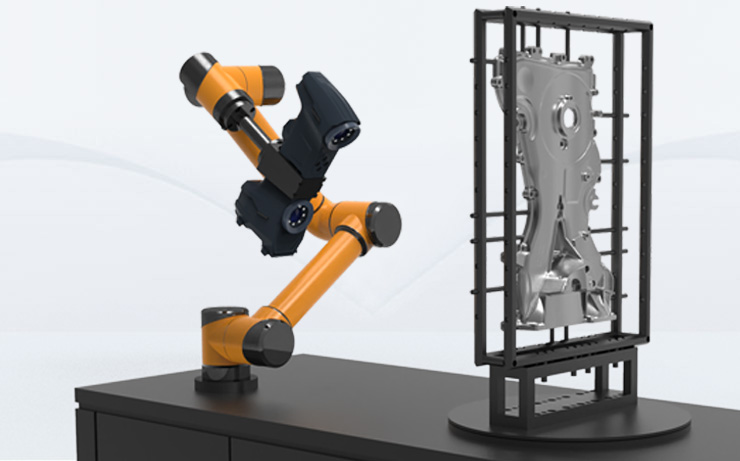

Multi-mode switching scan

Multi-mode switching scanning, switching multiple scanning modes for different scanning surfaces, allows scanning to meet both timeliness and high-precision standards, which can greatly speed up the inspection progress in full-size inspection.

Industrial grade high precision

Independently developed software equipment provides a mid-return scanning function to maintain the real-time nature of data scanning. The industrial-grade configuration brings high-precision scanning quality and provides strong support for subsequent detection.

Aircraft impeller STL data chart

Aircraft impeller STL data chart