- A +

- A

- A -

Aircraft blades are a special part. They are numerous, complex in shape, demanding, and difficult to process. Moreover, they are fault-prone parts and have always been the key to the production of various engine factories. Therefore, the human, material and financial resources invested in them are all It is relatively large, and domestic and foreign engine manufacturers are making their greatest efforts to improve the performance, production capacity and quality of blades to meet market needs.

Physical picture of aircraft blades

1.The blade parts have thin walls, large distortion of the blade body, and complex shapes, which are prone to deformation, seriously affecting the processing accuracy and surface quality of the blades. How to strictly control the machining errors of the blades and ensure good surface accuracy has become the focus of inspection work.

2.Traditional detection methods cannot scientifically guide the production and processing of blades. Advanced technology is reflected in the improvement and innovation of blades. Therefore, the level of blade manufacturing technology must be improved. At the same time, blade processing measurements are required to be digitalized to reflect their accuracy and accurately provide The error between the actual values of each blade point and the theoretical design of the blade.

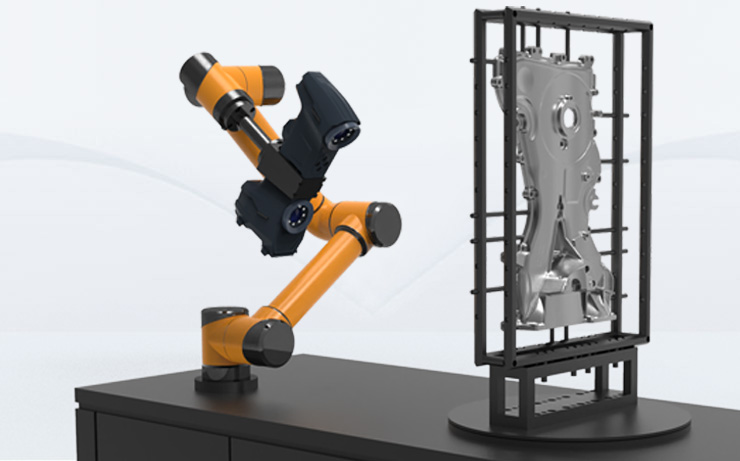

Aircraft blade scanning scene picture

Aircraft blade scanning scene picture

HOLON 3D technical engineers use the handheld 3D scanner Model 37 to quickly obtain accurate 3D data of aircraft blades, with a fast scanning imaging speed of 2070000 points/s. The unique advantages of the Model 37 3D scanner include strong applicability, wide range of applications, fast detection, and accurate results, making the 3D scanner widely used in blade manufacturing companies.

Use the handheld 3D scanner Model 37 to quickly scan and obtain 3D data of aircraft blades. Imported 3D software for data optimization and successfully solved the customer's problem of measuring blades. Achieve the accuracy and effect required by customers. It makes customers' design and processing more convenient and the research and development process faster.

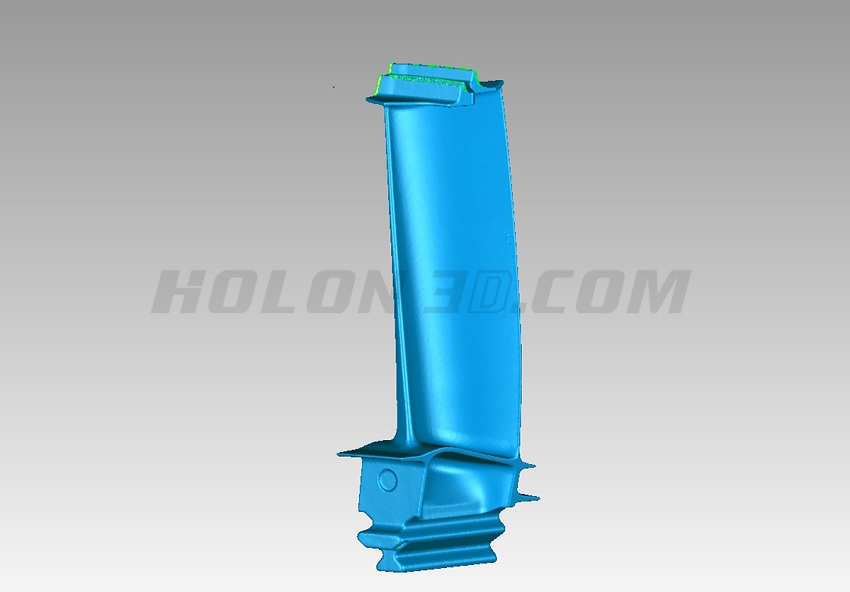

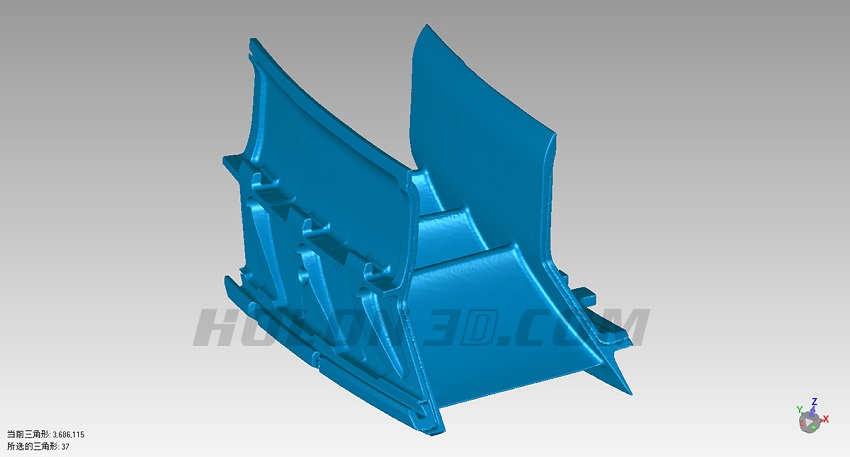

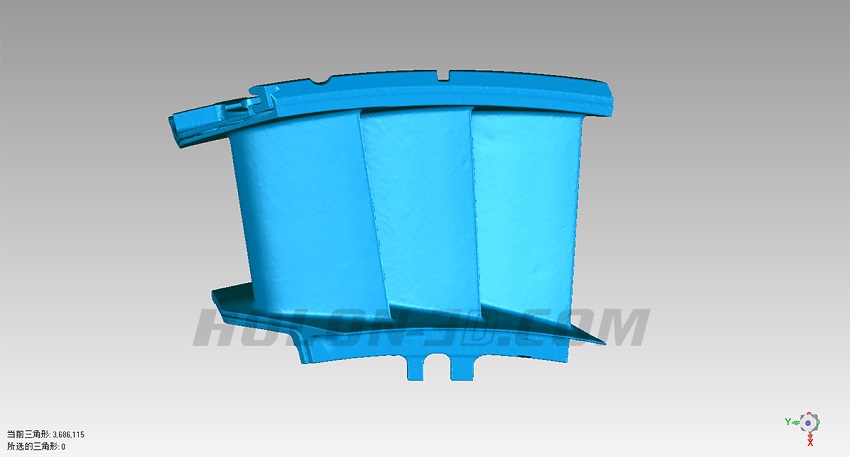

Aircraft blade STL data chart

Aircraft blade STL data chart

Aircraft blade STL data chart