- A +

- A

- A -

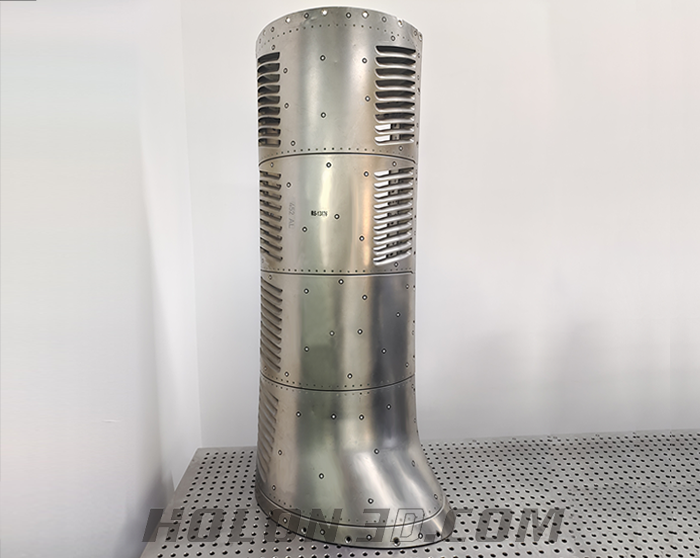

As the core power component of the aircraft engine, its external air bleed cover plays a crucial role in protecting it. At the same time, it can protect the engine and surrounding pipeline accessories, including the engine, circuit, oil line, brake system, transmission system, etc., fully protecting the normal operation of the aircraft.

1. The aircraft air bleed cover is made of titanium alloy. Several typical damage forms of titanium alloy may occur in aerospace engineering applications, including: fretting wear, fretting fatigue, hot salt stress corrosion, hydrogen embrittlement, low temperature, etc. The melting point metal causes brittleness and contact corrosion.

2. The aircraft engine air bleed cover has different groove shapes and porous positions on each surface. The structure is complex and fretting wear needs to be detected. Every place needs to be accurate. At the same time, the processing and inspection of geometric shapes require accurate data. For The airfoil cross-sectional area, alignment, and undulations require three-dimensional measurements in a non-destructive manner, which is a challenge for traditional measurement methods.

Actual picture of aircraft air bleed hood

Equipment used: HOLON 3D handheld three-dimensional scanner Model 37

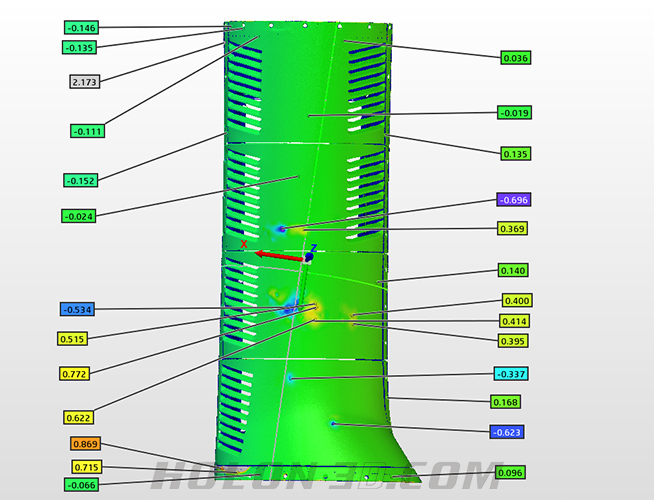

In response to the problems faced by customers, Hualang 3D engineers proposed a solution: use Model 37 handheld 3D scanner, which adopts the latest handheld design, is lightweight and easy to carry; 22 laser lines + 1 beam for deep hole scanning + 14 beams for fine scanning There are a total of 37 laser lines, and the three scanning modes can flexibly scan the variable cross-section of the aircraft air hood, and can accurately scan the uneven surface data of the hood and the data of each hole position; the data acquisition accuracy is high, and the data can be later inspected. analyze.

Aircraft bleed hood STL data chart

Comparative inspection chart of aircraft air bleed hood