- A +

- A

- A -

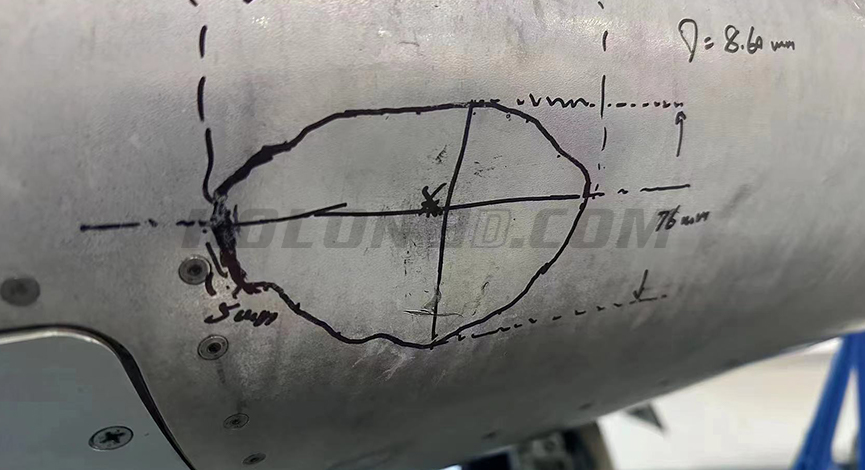

When an aircraft is flying at high altitudes for a long time, the high-intensity air pressure on the surface of the aircraft's outer shell and the friction and collision with objects in the air can easily cause large-scale dents. In order to ensure the stability of the cabin air pressure, the dented parts of the aircraft shell need to be repaired to ensure the safety of the aircraft during flight. sex, to achieve the purpose of extending the working time cycle of the aircraft.

Actual picture of the aircraft scene

1. In the traditional inspection method, maintenance engineers screen the surface through visual inspection. There are problems such as it is difficult to find small parts and the overall inspection range is not comprehensive enough.

2. The aircraft shell has a large area, so it takes a lot of time to screen, and it is difficult to ensure that there are no flaws.

Aircraft parts site diagram

Aircraft hull dent diagram

After the aircraft was disassembled, in order to quickly achieve the purpose of surface inspection, the manufacturer decided to use HOLON3D handheld 3D laser scanner Model 37 to conduct shell dent inspection.

High-precision three-dimensional inspection process:

· Smooth scanning, easy to scan: The new three-dimensional scanning detection method simplifies this tedious detection work, and can complete a component surface data scan in 5 minutes (600*550mm maximum scanning format measurement speed 2020000 times/ Second)

· High-precision scanning: Multi-mode scanning has better data capture capabilities on fine parts of the surface, bringing more accurate data presentation for subsequent comparison inspections. (Maximum accuracy of single frame is 0.01mm, stable repeatability)

· Simple, clear and easy to understand: Import the comparison software, compare with the original digital analog, export the comparison analysis chart with one click, compare it with the actual aircraft shell, and the surface depressions can be clearly seen.

Aircraft shell scanning site picture

Aircraft shell STL data chart

Aircraft shell comparison inspection chart

Through 3D scanning, defects in the aircraft shell can be quickly detected to determine the various risks of the aircraft shell. This high-precision handheld 3D scanner can be used in various aspects of aircraft manufacturing and inspection, effectively reducing the cost of aircraft inspection. Complexity helps aerospace accurate and efficient manufacturing