- A +

- A

- A -

A large German airline uses our 3D scanner combined with the photogrammetry system to conduct 3D measurements of the aircraft engine soundproof cabin to obtain ultra-high-precision 3D data, detect and analyze whether the product is qualified, and lay the foundation for later reverse design mold opening and processing, saving money. cost.

1. Due to the large size of the soundproof cabin of the aircraft engine, high surface precision requirements and inconvenience to move, when measuring with a camera-type 3D scanner, the cumulative error will be too large. How to eliminate the impact of the error is the biggest problem faced.

2. The use of traditional measurement methods not only takes a long time, but also obtains limited data and cannot accurately measure the three-dimensional data of the aircraft engine soundproof cabin surface, making it impossible to perform complete scanning and data splicing. It is also impossible to complete the quality inspection of the aircraft engine soundproof cabin.

In response to the problems faced by the company and scanning objects, HOLON technical engineers proposed a solution: using the photo scanner HL-3DS+ and the three-dimensional photogrammetry HL-3DP to quickly and accurately obtain the three-dimensional data of the aircraft engine soundproof cabin combined with reverse design The software provides powerful data for the detection, design and mold opening processing of aircraft engine soundproof cabins, solves all problems faced, and meets customer needs.

Aircraft engine soundproof cabin scanning site

Aircraft engine soundproof cabin photogrammetry shooting scene

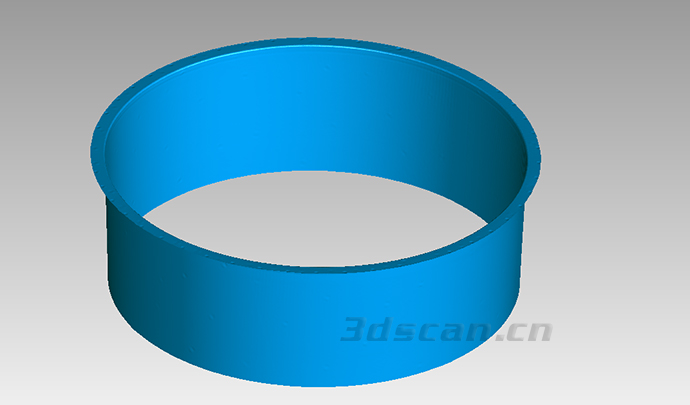

Aircraft engine soundproof cabin STL data chart

Aircraft engine soundproof cabin STL data chart

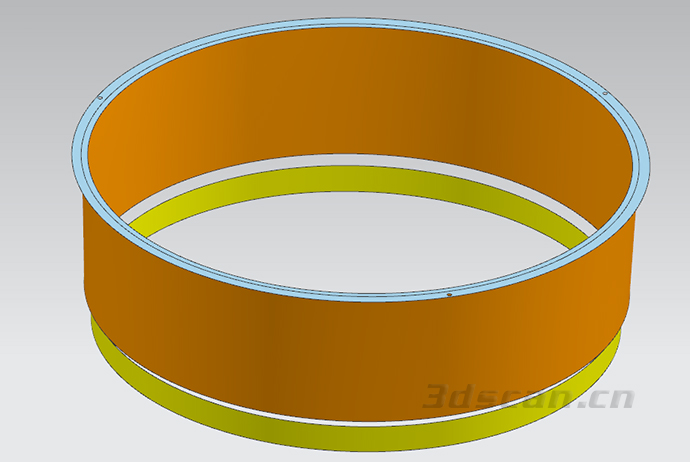

3D data diagram of aircraft engine soundproof cabin

3D data diagram of aircraft engine soundproof cabin