- A +

- A

- A -

Gastroscopes are medical equipment with high quality requirements. The rationality of design in all aspects is very important. In order to design a more competitive gastroscope handle, the manufacturer uses a new measurement method to scan and reverse test the gastroscope handle. There are some unqualified detections. If there are any defects, the appearance and details of the gastroscope handle can be more rationally improved to improve production efficiency and product quality.

The gastroscope handle performs three-dimensional scanning for reverse detection, and customers have high requirements for scan data accuracy. The handle operating head has a complex structure, has various operating functions, and has high requirements for detailed scanning.

When using traditional measurement methods cannot solve the problem, our engineers use the handheld 3D scanner Model 41 to perform 3D scanning to obtain comprehensive 3D data according to the requirements of the customer. The equipment is simple to operate, the scanning speed is extremely fast, and the single-machine volume accuracy is high. During the scanning process, the data will be displayed on the computer in real time. The scanning data is highly accurate and complete, and the scanning effect is very good in details.

Import the scanned 3D data into the 3D software for processing, detection and analysis. The analysis report is easy to understand and users can intuitively understand the quality problems of the product. The scanner has fast scanning speed and high accuracy, and can be completed by one person, saving manpower and improving work efficiency, and solving problems in a short time. Obtaining data can help customers solve problems, improve designs, and improve quality.

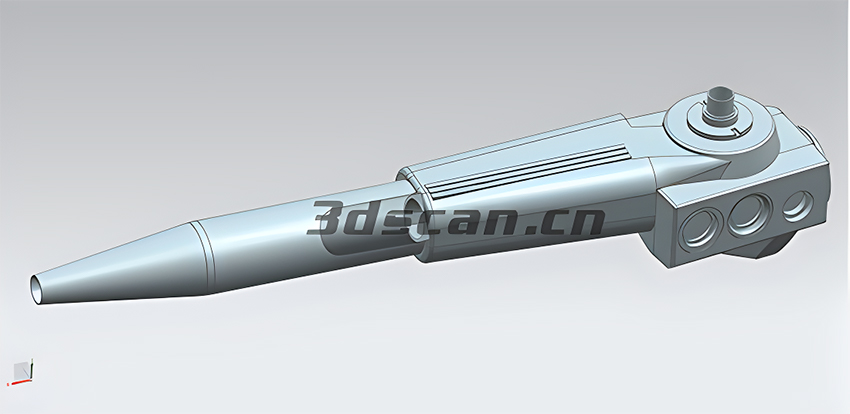

Gastroscope handle STL data chart

Reverse physical picture of gastroscope handle