- A +

- A

- A -

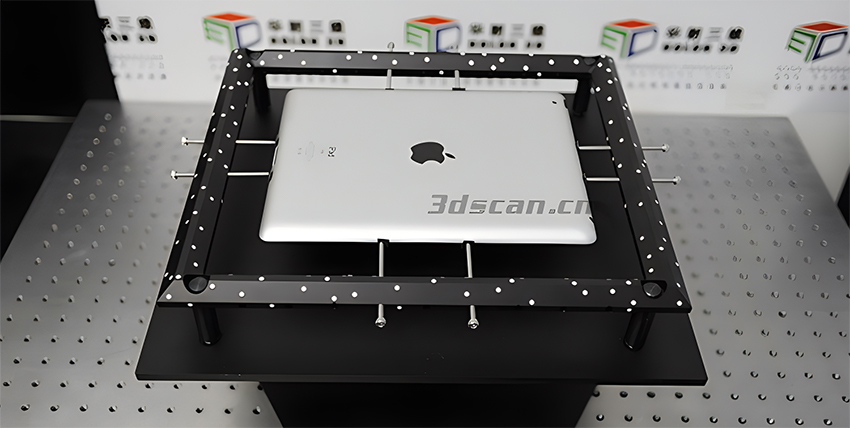

An electrical appliance manufacturing company hopes to obtain the three-dimensional data of the tablet computer shell through the three-dimensional scanner HL-3DM, and establish the three-dimensional data of the computer shell for modification and subsequent quality inspection and quality control.

Tablet PC scene picture

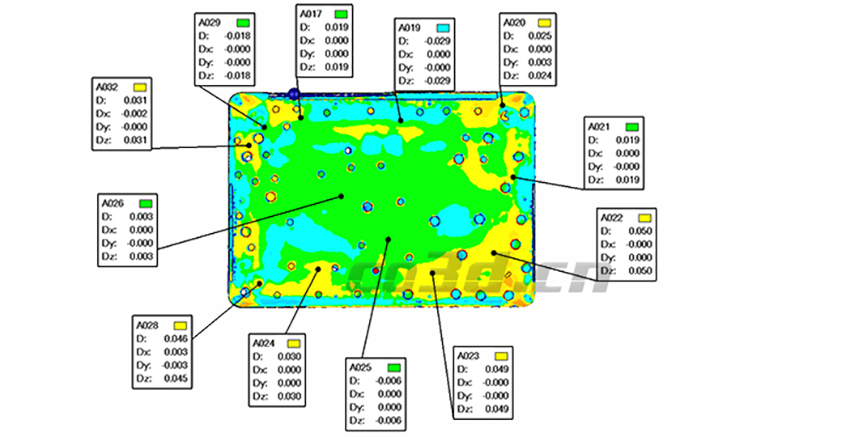

1. Customers have very high accuracy requirements for the three-dimensional data of earphone diaphragms, and the overall error needs to be controlled below 0.02mm.

2. Using traditional measurement methods, only part of the tablet casing can be measured, and the curved surface part cannot be measured, resulting in incomplete data acquisition and inability to detect the tablet casing.

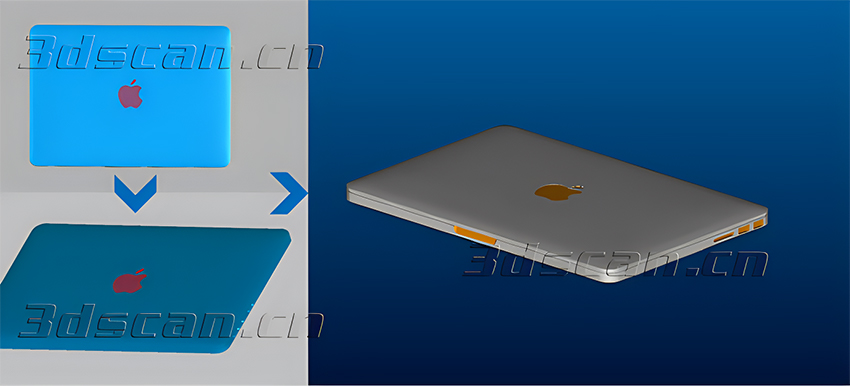

1. First, Hualang 3D engineers used the 3D scanner HL-3DM to scan the actual flat panel casing to obtain high-precision point cloud data, and processed it with supporting software to obtain a 3D model in STL format.

Tablet PC case STL data chart

2. Import the three-dimensional measurement data into the reverse modeling software for reverse modeling.

Tablet PC case 3D data chart

3. Import the obtained three-dimensional data of the tablet computer into the detection software to quickly detect the differences between the tablet computer (CAD) model and the manufactured parts of the product, and display the differences between the two with intuitive and easy-to-understand graphical comparison results.

Comparative analysis chart of tablet computer casing