- A +

- A

- A -

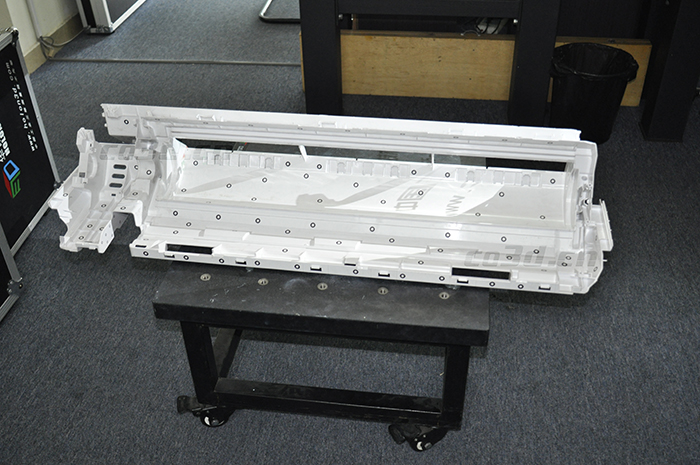

GREE air conditioning manufacturing company because of the quality of air conditioning shell production is not clearance, greatly delayed the production of air conditioning. The company hopes to quickly and accurately access to three-dimensional data of air conditioning, to provide data support for the two design of the air conditioning enclosure and quality inspection.

Practical problems

1, the traditional measurement method, the obtained data is limited and can not accurately express the 3D data of the surface, also can not carry on the two design and quality inspection of the later stage of the air conditioner shell.

2, the outer shell of the air conditioner needs to be matched with the internal parts, and the accuracy of the 3D data of the air conditioner is very high.

solutions

Air conditioning shell design will affect the overall quality of the air conditioning, customers need to obtain the original air conditioning housing data, in the original design based on better products. According to customer demand, Huaguang 3D technology engineers use 3D scanner HL-3DS, not in contact with the object mode, 3D data model convenient and quick access to the air conditioner casing. With advanced reverse design means to speed up product design and production speed.

GREE air conditioner shell

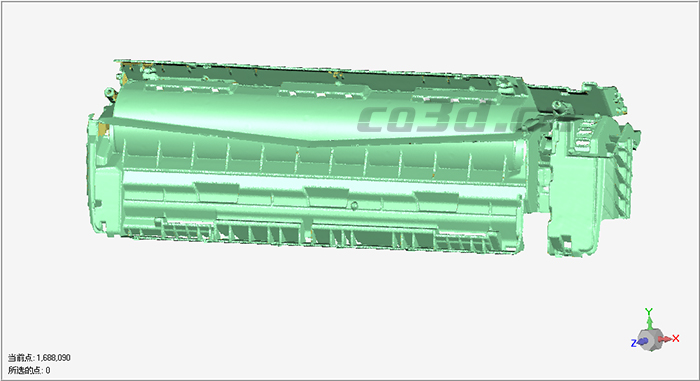

1, the first use of three-dimensional scanner HL-3DS air conditioning shell kind of scanning, to obtain high-precision, high-precision point cloud data.

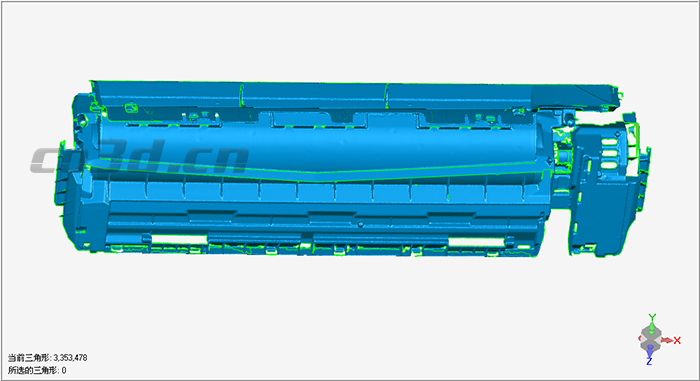

2, through the reverse design software Studio Geomagic to get the three-dimensional model of the air conditioner shell STL format;

3, the air conditioning shell 3D data import reverse modeling software (Pro/E, UG) for reverse modeling;

4, the use of reverse modeling software to process the CAD data, can be used for the processing of CNC machine tools, rapid prototyping, appearance quality inspection, etc.;

GREE air conditioner shell STL data

GREE air conditioning shell point cloud data