- A +

- A

- A -

With the rapid rise of intelligent mobile phone market, consumers higher quality requirements for the intelligent mobile phone and mobile phone shell in the huge market demand completely rely on manual testing can not meet the requirements of production, use of mobile phone shell 3D scanner three-dimensional detection to improve production efficiency, promote industrial upgrading is the inevitable trend of development of the industry.

Practical problems

1 the traditional measurement method is not enough to collect the data, which can not be measured on the irregular surface of the cell phone surface. Unable to detect the normal cell phone surface.

2 the production of the cell phone surface will change, the error will increase, the use of three-dimensional scanner can shorten the detection time, reduce the quality of the production of mobile phone surface.

solutions

Cell phone surface shell

Case profile:

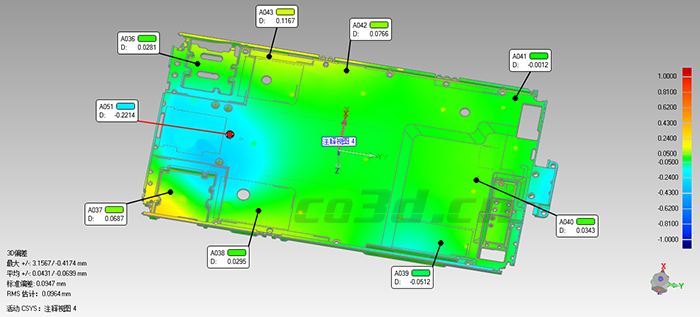

A domestic mobile phone manufacturer, to detect whether or not produce mobile phone shell quality, decided to use 3D scanner to detect 3D Huaguang mobile phone shell, by contrast test report, Huaguang three-dimensional 3D scanning combined with their years of experience, rich experience in testing and solutions has detected in the mobile phone shell, mobile phone, mobile phone motherboard shell surface defect.

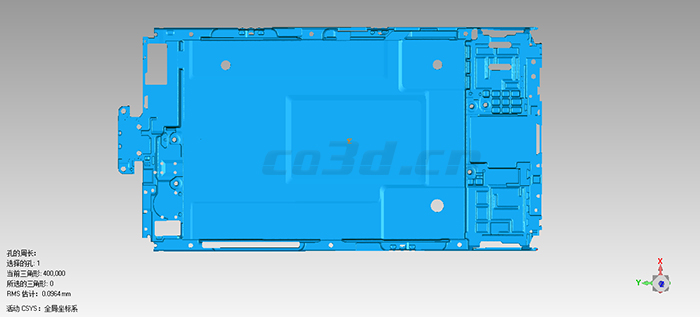

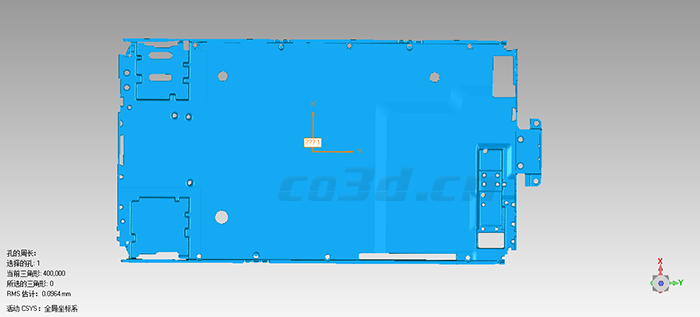

Mobile phone shell STL data

Scanning device:

The 3D precision Huaguang 3D scanner HL-3DM

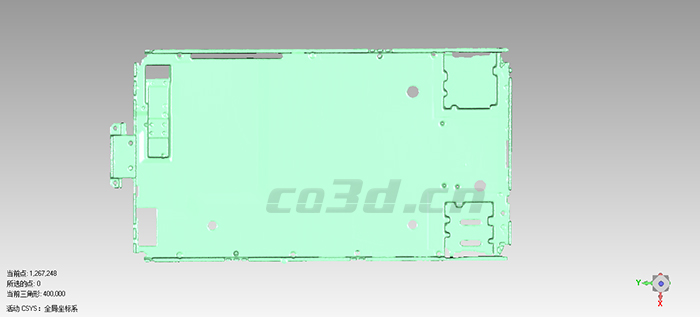

Mobile phone surface shell point cloud

Field of application:

Precision molds, 3C products, electronic components, jewelry scanning, electronic security plug-ins and other applications.

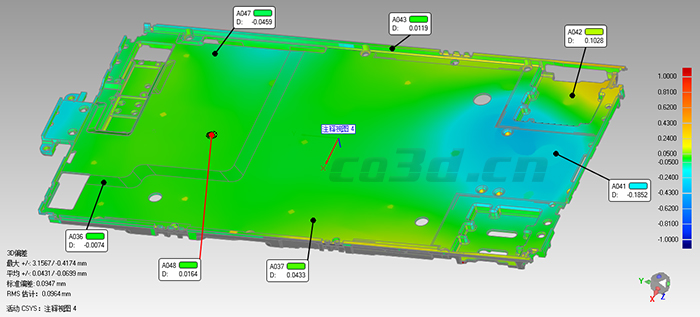

Mobile phone surface shell contrast detection data

Product features:

High precision data motherboard: the German high precision measuring instrument, the motherboard data up to 0.0002mm.

The scanning speed: less than 3 seconds can get millions of data points, high efficiency (can also be customized according to customer demand system).

The high precision measurement technology: the use of unique, single scanning accuracy is less than 0.005, with the 3D photogrammetry system, higher precision.

- mark point automatic stitching: scanning process real-time display automatic stitching, scanning objects can be arbitrary flip and move.

3D data of cell phone surface

Mobile phone surface shell data