- A +

- A

- A -

A well-known VR glasses manufacturer in China hopes to quickly acquire the original appearance data of VR glasses through 3D scanners to make product packaging boxes and secondary design of later products, accelerate the development of new products and improve production efficiency.

Practical problems

1. The shape of VR glasses is complex, the contours of each surface are different, and the curved surface and dead angle are more shadows. The use of other testing equipment may result in incomplete 3D data acquisition and cannot meet customer needs.

2, the use of traditional measurement methods (such as inspection tools, fixtures, three coordinates, etc.) is very cumbersome and time consuming. Moreover, it is not easy to accurately and quickly measure and detect the structural appearance data of VR glasses, and it is not conducive to the later product development.

solutions

According to the customer's problems and scanning needs. Huaguang 3D engineers provide professional solutions: using the camera-type 3D scanner HL-3DX (quickly acquiring high-precision 3D data of VR glasses) + reverse design software Geomagic Studio (converting VR glasses point cloud data into triangular mesh surface data) Assisting the company in the production of VR glasses product packaging boxes to meet customer needs and solve problems faced by customers

VR glasses physical map

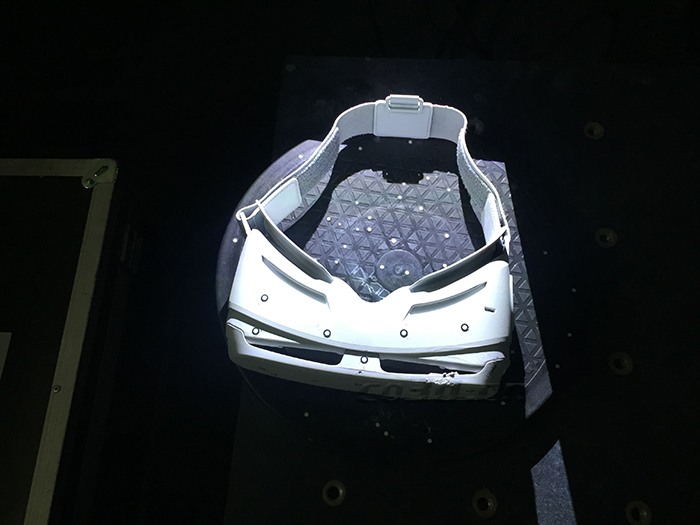

VR glasses 3D scanning scene

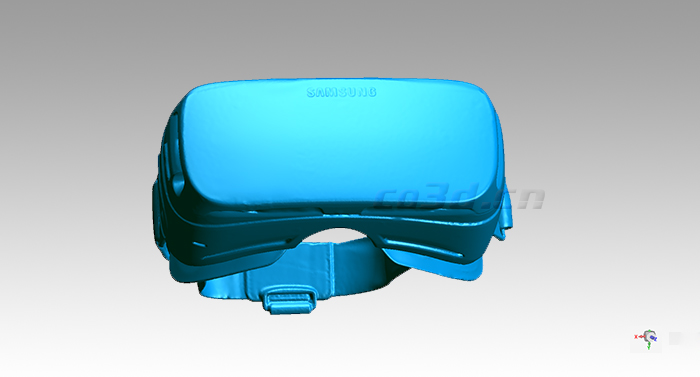

VR glasses STL data map

VR glasses STL data map

VR glasses STL data map

VR glasses STL data map