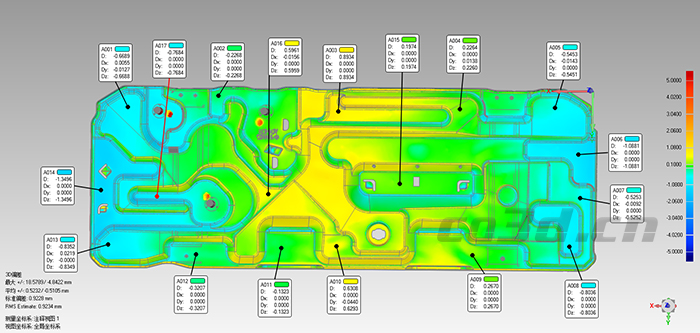

- A +

- A

- A -

Air conditioning sheet metal stamping forming process and the shape of complex surface, Flat warp, wrinkle and other characteristics, for the production of sheet metal parts and air conditioning problems or defects, Huaguang 3D scanner provides detection scheme for the enterprise to optimize the design parameters of the stamping process and die etc..

Practical problems

1 air conditioning sheet metal parts with complex shape, surface Flat warp, wrinkle, the traditional measuring instruments can not be effective for air-conditioning sheet metal parts.

solutions

Case profile:

A domestic air-conditioning production group, in order to solve the production of air conditioner sheet defects, decide on the air conditioner sheet is scanned using Huaguang 3D scanner, contrast detection and original model diagram, for the enterprise to provide the solution for optimization of stamping process.

Scanning device:

Huaguang HL-3DS+ 3D scanner

Product features:

The scanning speed: less than 3-5 seconds can get millions of data points, high efficiency (can also be customized according to customer demand system)

- high precision: single scan precision of 0.01mm and compatible Photogrammetry System with photography allows faster scanning speed and higher precision, 0.0125mm/m.

The patented design: to eliminate the common 3D scanner multi angle scanning on the problem of cumulative scanning precision, scanning data without deformation, and other steps, fringe scanning mode, easy adjustment, suitable for various requirements of the workpiece.

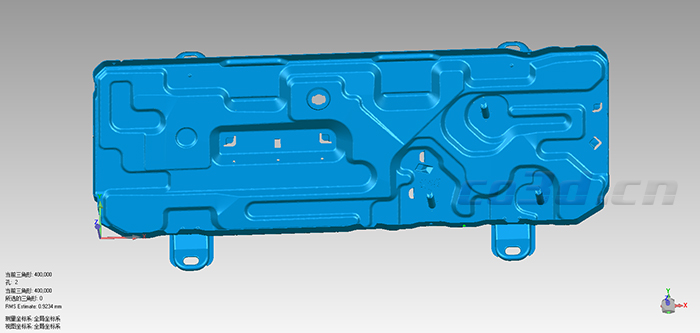

Air conditioning sheet metal scanning spot

Scanning STL data of air conditioning sheet metal parts

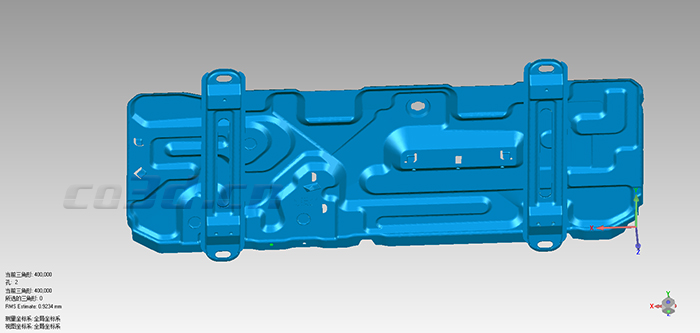

Scanning STL data of air conditioning sheet metal parts

Comparative analysis data with original data