- A +

- A

- A -

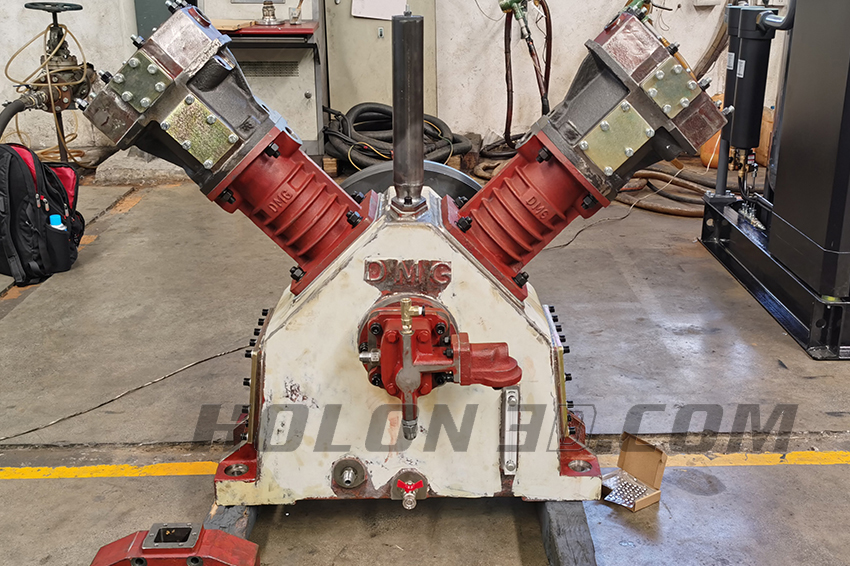

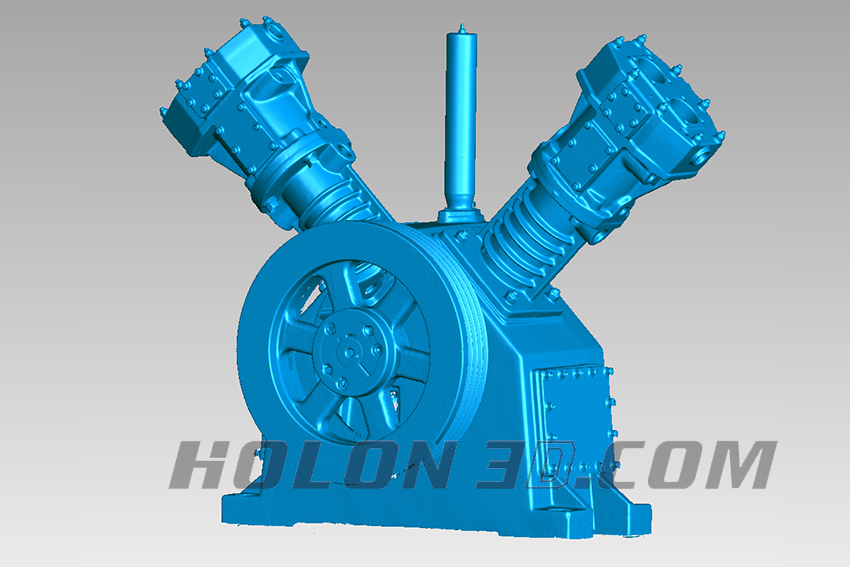

The compressor is a driven fluid machine that elevates low-pressure gas to high-pressure gas. It is the heart of the refrigeration system. It sucks in low-temperature and low-pressure refrigerant gas from the suction pipe, drives the piston to compress it through the operation of the motor, and discharges the high-temperature and high-pressure refrigerant gas to the exhaust pipe to provide power for the refrigeration cycle. A compressor manufacturer needs to conduct three-dimensional scanning of compressor parts.

Compressor physical picture

Physical pictures of compressor parts

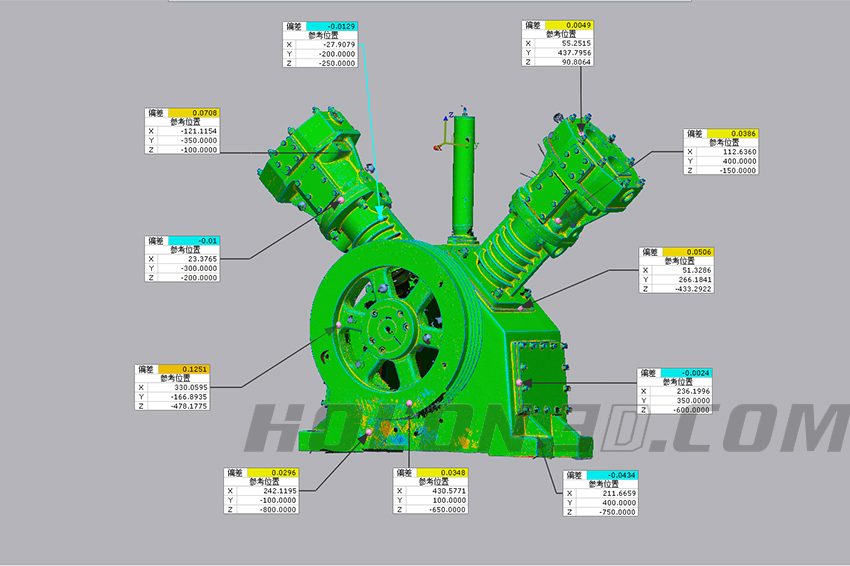

The workpiece is larger in size and weight, and has many uneven details on the surface. The difficulty of collecting part detail data is greatly increased. Customers have high requirements for the accuracy of part scanning. Traditional measurement methods are difficult to meet customer needs.

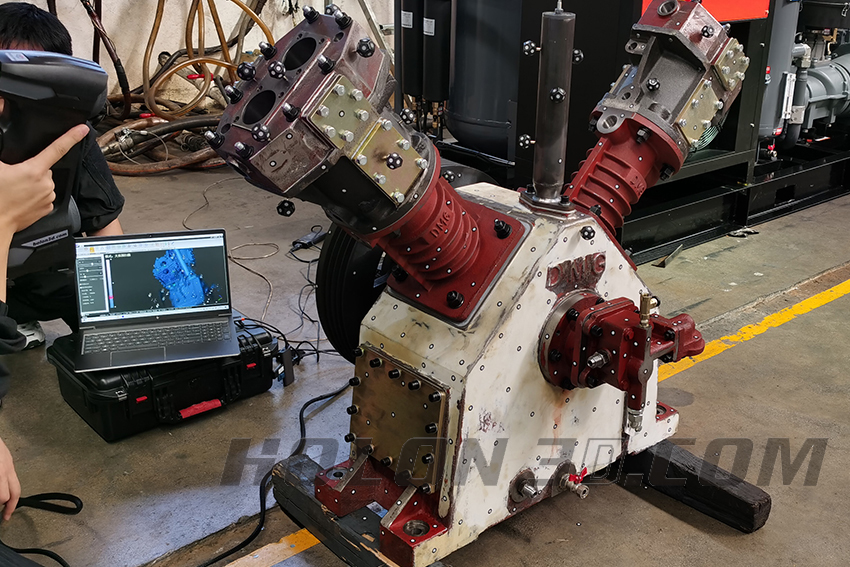

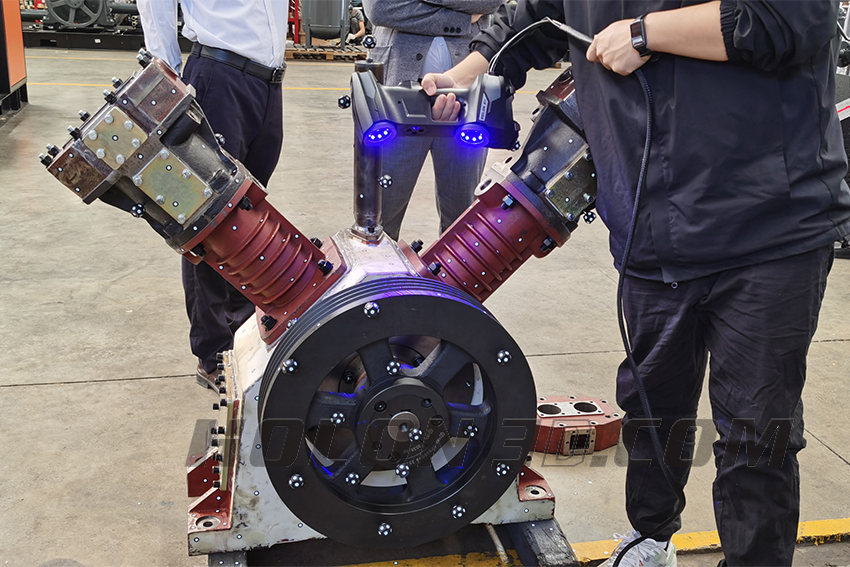

On-site scan of compressor parts

On-site scan of compressor parts

HOLON3D engineers use the handheld 3D scanner Model 49 to scan large workpieces, using the wide-area mode to maximize the use of cross lasers to quickly capture data and generate contour data instantly. For various features of the workpiece, the corresponding scanning mode can be quickly switched, and even the smallest features of the part can be perfectly captured. The maximum scanning accuracy can reach 0.01mm. The scanned 3D data can be subsequently used for 3D inspection, reverse design, reverse modeling, etc. to improve work efficiency and solve customer needs.

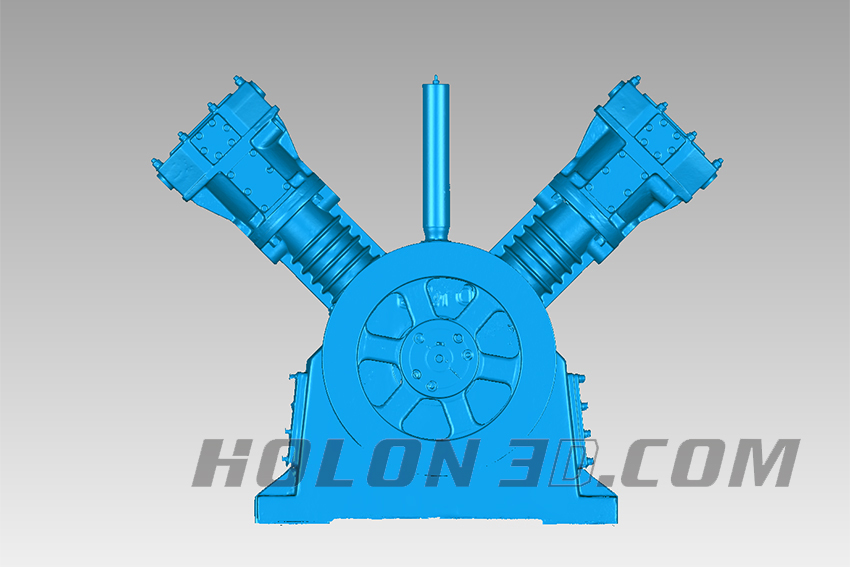

Compressor parts STL data chart

Compressor parts STL data chart

Compressor parts STL data chart

Compressor parts inspection comparison data chart