- A +

- A

- A -

A gas turbine is an internal combustion power machine that uses continuously flowing gas as the working fluid to drive the impeller to rotate at high speed, converting the energy of the fuel into useful work. It is a rotating impeller heat engine. The combustion chamber and turbine have high operating temperatures and are also subject to thermal shock caused by drastic temperature changes when the gas turbine is started and stopped. Therefore, they are key components that determine the life of the gas turbine. There are problems in scanning arc sections of steam turbines to obtain data for analysis, and to improve work efficiency, the use of automated three-dimensional measurement methods can provide suitable solutions.

The gas turbine is large in size, and the arc section that needs to be inspected cannot be separated. The arc of the section is large, which makes traditional inspection work difficult. Moreover, the customer requires that the inspection speed must be fast without sticking points or powder spraying.

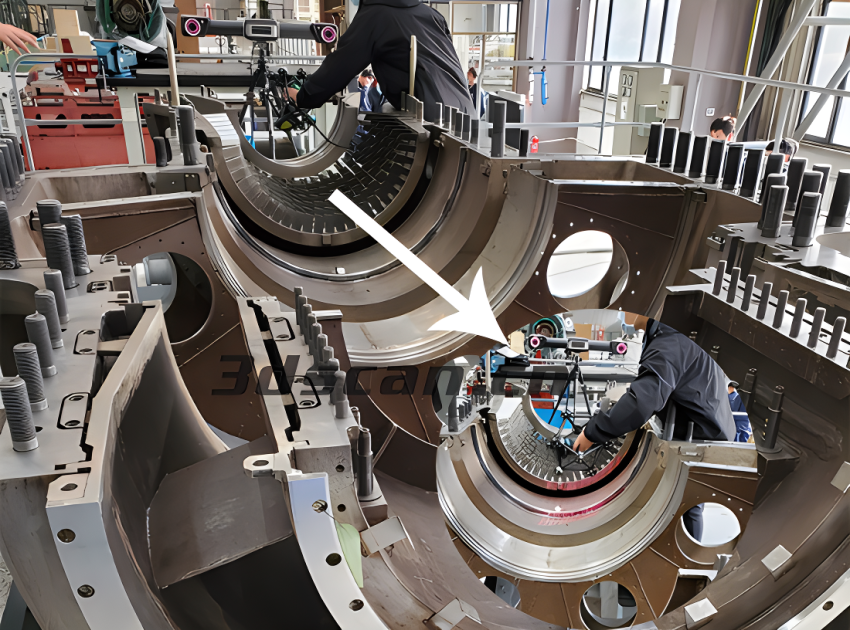

Real photos of gas turbines on site

Using traditional manual measurement methods is very cumbersome and time-consuming, reduces work efficiency, extends the project deadline, and obtains incomplete data, which cannot meet customer needs.

Gas turbine site scan

Equipment used: T-SCAN automated 3D measurement system

Gas turbine site detail scan

Gas turbine arc section inspection uses the HOLON 3D T-Scan 3D online inspection system combined with the latest 3D scanning technology to effectively scan the gas turbine. The process does not require spotting or powder spraying, and is easy to operate. It can be taken and scanned. The handheld model is convenient for mobile scanning. The scanning speed is fast and the accuracy is high. High-precision three-dimensional data can be obtained in a short time. It can also cooperate with robot scanning to reduce manual intervention, realize automated detection and improve work efficiency.

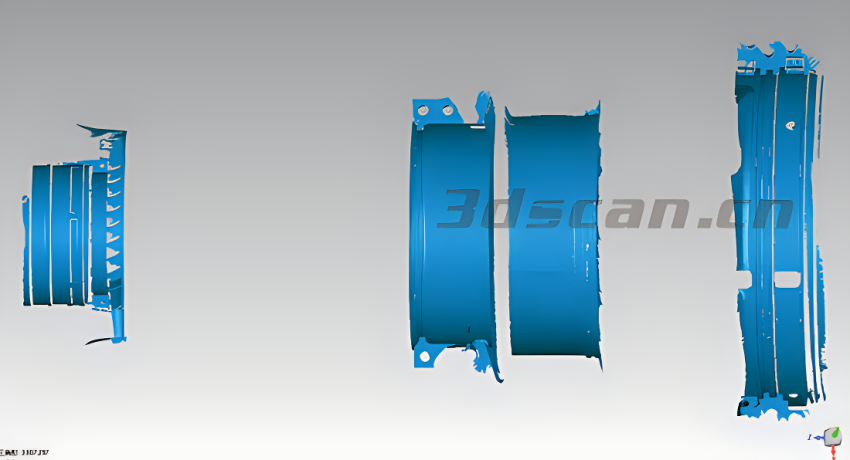

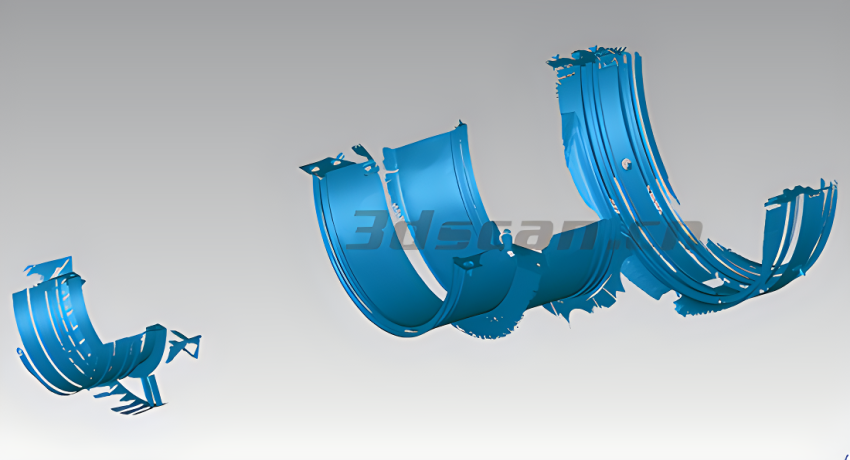

Gas turbine arc surface STL data diagram

By importing the acquired data into the 3D inspection software, you can quickly obtain detailed arc sections and original digital and analog 3D inspection reports, clearly understand the existing problems, effectively solve the problems faced by customers, realize automated scanning and inspection, and greatly improve work efficiency, thus Shorten product development, design and processing cycles and reduce production costs.

Gas turbine arc surface STL data diagram

Gas turbine arc surface STL data diagram