- A +

- A

- A -

As an important logistics equipment, forklift is widely used in logistics, warehousing, production and other industries. It can achieve fast loading and unloading, stacking and short distance transportation of goods, thereby significantly improving work efficiency and reducing the labor intensity and time required for manual handling. Forklifts use a variety of automatic pick-up devices, in the case of fork and pallet use, can achieve complete mechanization of loading and unloading work, reducing the dependence on workers to assist physical labor. Forklift can be applied to warehouses, stations, docks and ports and other occasions, supplemented by pallets together can also greatly improve the efficiency of operation and save labor. Therefore, in order to ensure the life safety of operators and extend the service life of forklifts, it is particularly important to carry out three-dimensional detection of forklifts regularly.

The problems of forklift scanning, forklift body is large, body casting structure is complex. The irregular shape is difficult to detect, and it is necessary to measure whether the body of the forklift truck matches the front assembly.

Forklift body scanning scene

HOLON3D technical engineers use the industrial-grade 3D scanner Model49 with scanning speeds of up to 420points/s, a maximum scanning accuracy of 0.01mm in precision mode, and a scanning area of up to 600 mm x 550 mm. This scan uses both large range mode and standard mode, which can easily handle the scanning of large workpieces. Collect the 3D data of the entire body and the front part, scan it in just 30 minutes, and export the 3D detection analysis report, providing effective solutions for enterprises.

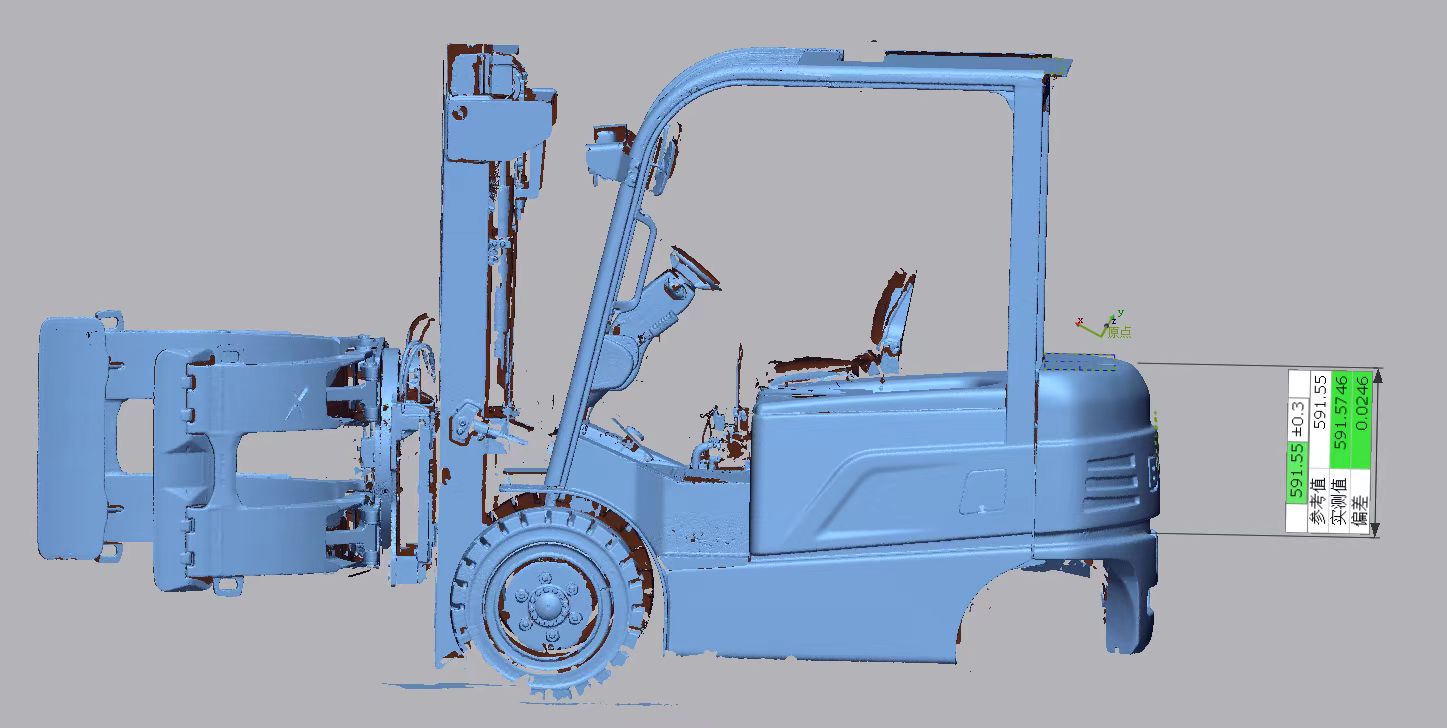

Forklift body STL data diagram

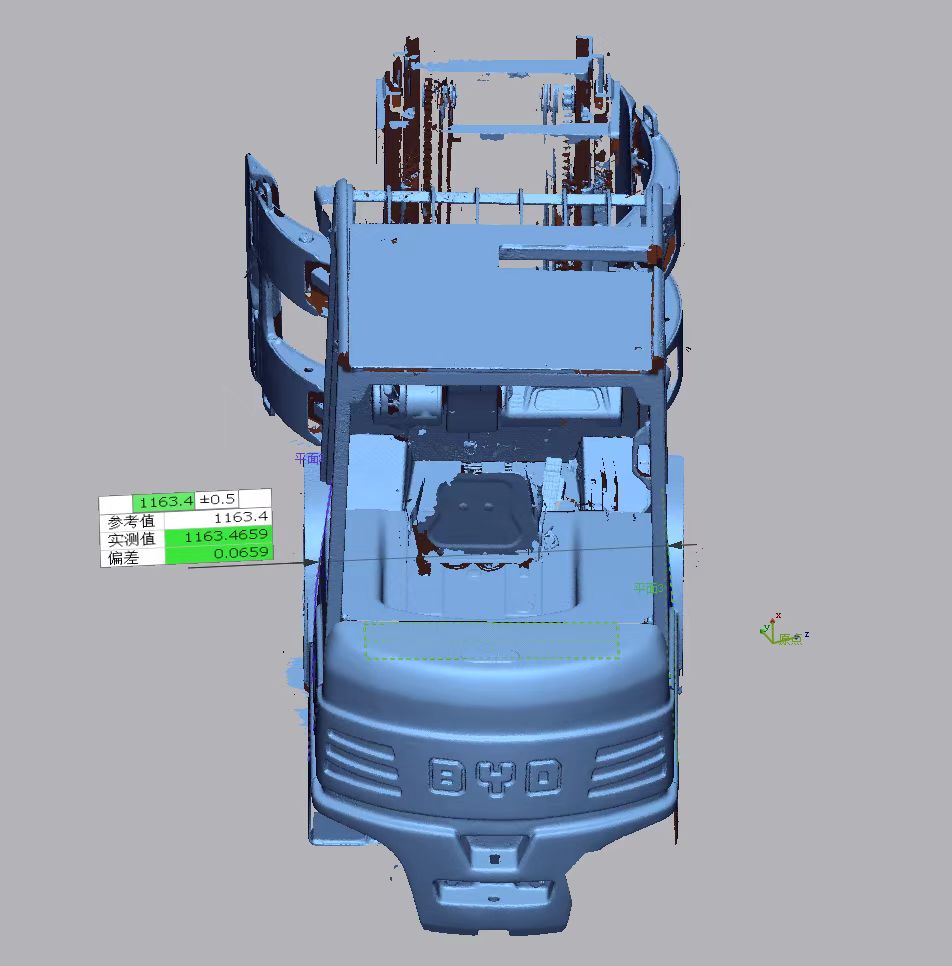

Forklift body comparative analysis diagram