- A +

- A

- A -

Steam turbine is a prime mover, which can directly convert the heat energy of steam into rotating mechanical energy. It is to make steam expand in the nozzle, reduce the pressure, increase the speed, convert the heat energy into kinetic energy, and then convert the kinetic energy of steam into the mechanical energy of the rotation of the blade shaft. Steam turbine is one of the three main equipment of power plant, which drives the generator to rotate and produce electric energy. The cause of cylinder deformation is related to the thickness and structural size of the cylinder wall and flange metal, the operation of the flange and bolt heating in the start and stop working condition, and the cylinder heat preservation condition also has a certain relationship, and the manufacturing process. Due to the aging problem of the cylinder casting, as well as the complex force situation, the cylinder deformation is an inevitable problem, which is usually manifested as the cylinder has an internal opening or an external opening, and the low pressure cylinder is more prone to this problem.

In the process of steam turbine operation, steam turbine leakage and cylinder deformation are the most common equipment problems, the tightness of the cylinder joint surface directly affects the safe and economic operation of the unit, maintenance and scraping of the cylinder joint surface to make it strict, is an important work of cylinder maintenance, in the process of dealing with the leakage of steam on the joint surface, it is necessary to carefully analyze the causes of formation.

Turbine site physical picture

Turbine field scan

Turbine field scan

According to the degree of deformation and the size of the clearance, the customer uses the HOLON3D handheld Mdeol49 scanner to detect the deformation of the turbine. Aiming at the diversity of parts and the registration of assembly, the product ensures the integrity and accuracy of the measurement data through a variety of scanning modes; The use of fine mode, so that small features nowhere to hide, the highest scanning accuracy of 0.01mm; For measurements of large parts, the large range mode rapidly captures data (4,200,000 points/s), increasing the measurement speed. The customer is very satisfied. HOLON3D is proud of technological innovation, and the metrological 3D scanner shows the strength of the manufacturer. Side by side with customers, a new chapter of industrial intelligent manufacturing.

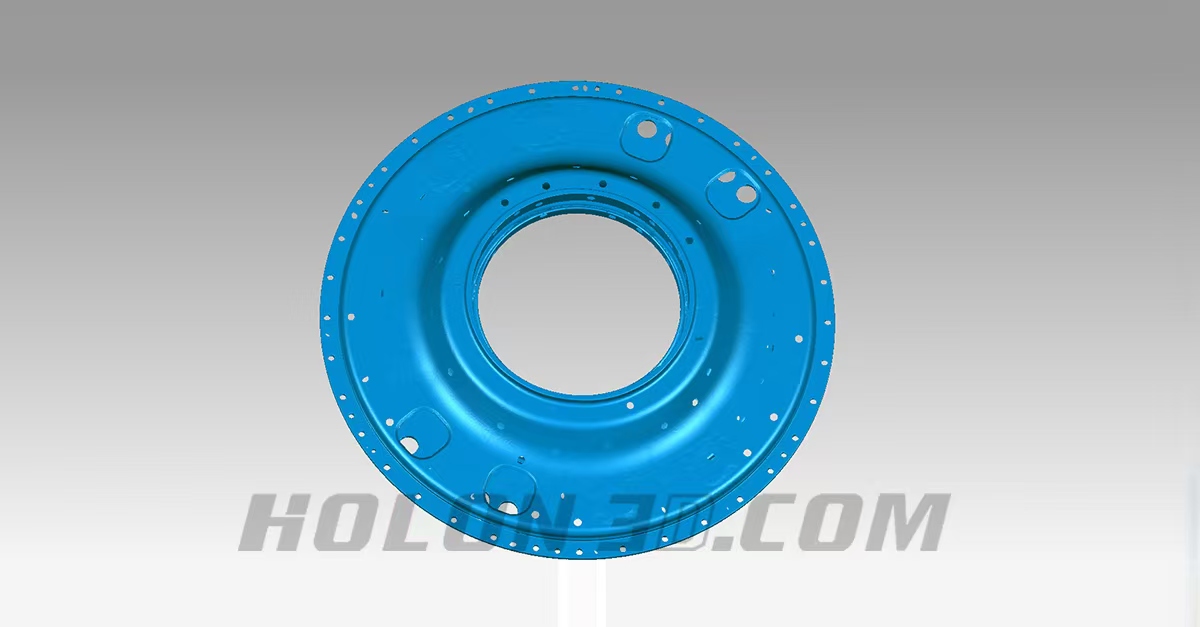

Turbine STL data diagram