- A +

- A

- A -

A large CNC manufacturing company needs to conduct three-dimensional inspection of large-scale composite molds after machining to obtain high-precision three-dimensional data. HOLON3D engineers use the three-dimensional photogrammetry system HL-3DP to detect whether the production of large composite molds is qualified.

1. The size of the large composite mold (about 7 meters long and 2 meters wide) is large, difficult to move, has uneven edge contours, and has many grooves on the rhombus surface. Traditional measuring tools (such as inspection tools, two-dimensional, three-dimensional coordinates, etc.) cannot perform inspection work at all.

2. Due to the large volume and inconsistent contours of composite molds, using a traditional 3D scanner takes a long time, the data quality is low, and the errors are large, making it unable to meet the customer's quality inspection of large molds.

In view of the large scanning area of the company's large composite molds, in order to eliminate the problems of accumulated scanning errors and complete splicing, HOLON3D technical engineers proposed the use of a solution: the three-dimensional photogrammetry system HL-3DP to quickly obtain high-precision three-dimensional data of large molds + reverse design Software (converts large mold point cloud data into triangular mesh surface data) + imports into design software for post-processing to obtain inspection and analysis reports.

Preparation work before large mold inspection

Large mold inspection site

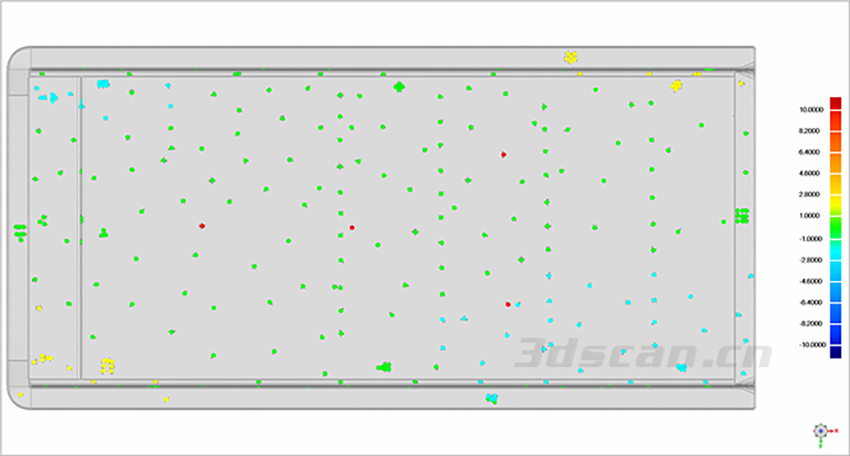

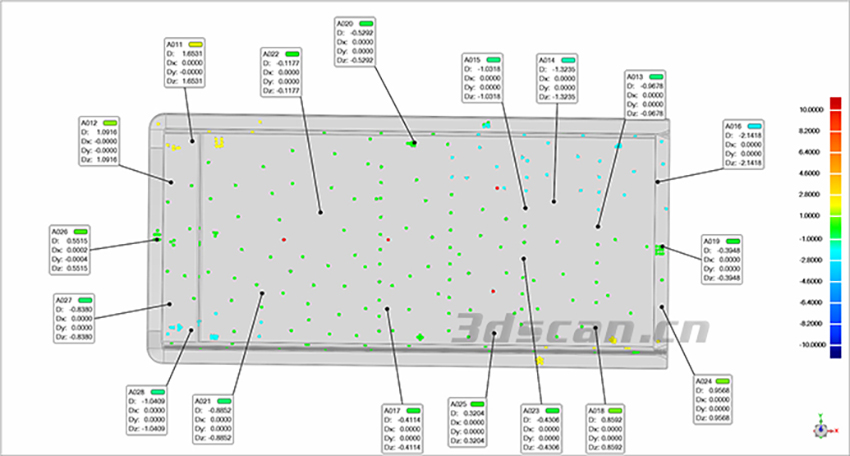

Large mold 3D data chart

Large mold 3D data chart