- A +

- A

- A -

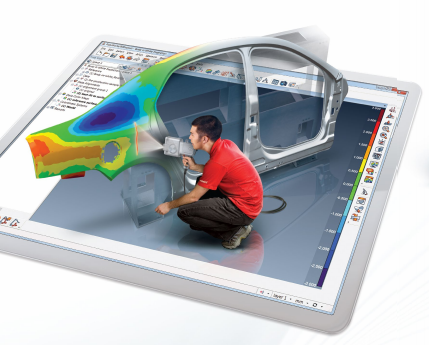

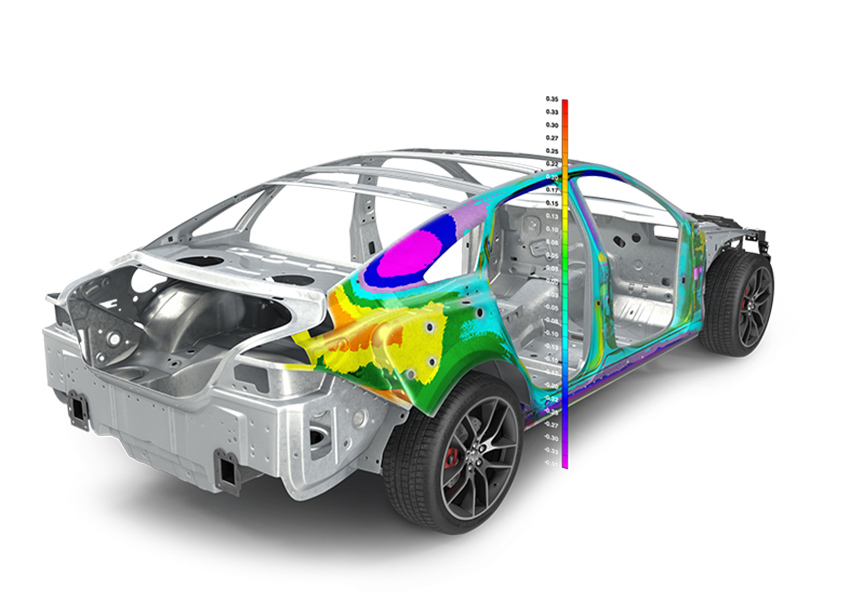

PolyWorks | inspector is a versatile 3D dimensional analysis and quality control software solution that controls tool or part dimensions, identifies and avoids manufacturing and assembly issues, guides installation through real-time measurements, and oversees assembled products through the use of portable measurement equipment and CNC CMMs the quality of.

Full-featured dimensional analysis and quality control toolbox

The core of PolyWorks | Inspector is a powerful inspection engine with parametric data processing capabilities, PTB-certified mathematical algorithms, and comprehensive visual and auditory feedback functions. Users can leverage it to extract meaningful information from the 3D data they measure, automate inspection processes when measuring multiple workpieces, and structure measurement results reporting to facilitate digital collaboration across the enterprise.

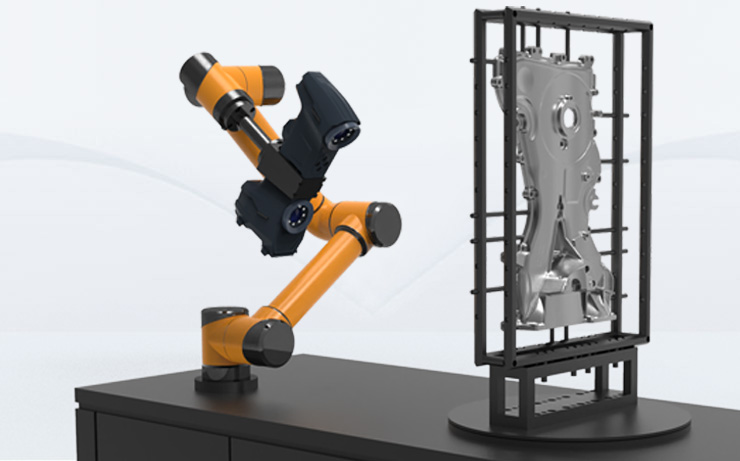

Market-leading portable measurement platform

PolyWorks | lnspector is known for its powerful and stable direct hardware interface. It provides an extensive set of guiding technologies that the world's largest industrial manufacturing companies trust to deliver efficient, accurate and repeatable measurement processes for portable measurement equipment.

Efficient CNC CMM solutions

In a flexible, user-friendly and efficient CNC CMM operating mode, PolyWorks | Inspector revolutionizes the way you set up and execute inspection projects on CNCCMM, making it an operating mode similar to what we offer on portable measurement equipment.

Universal software platform

Only one piece of software is required to master, thus empowering measurement experts! Measurement barriers are eliminated, employee mobility is increased and overall teamwork efficiency is improved, which significantly reduces a company's operating costs.