- A +

- A

- A -

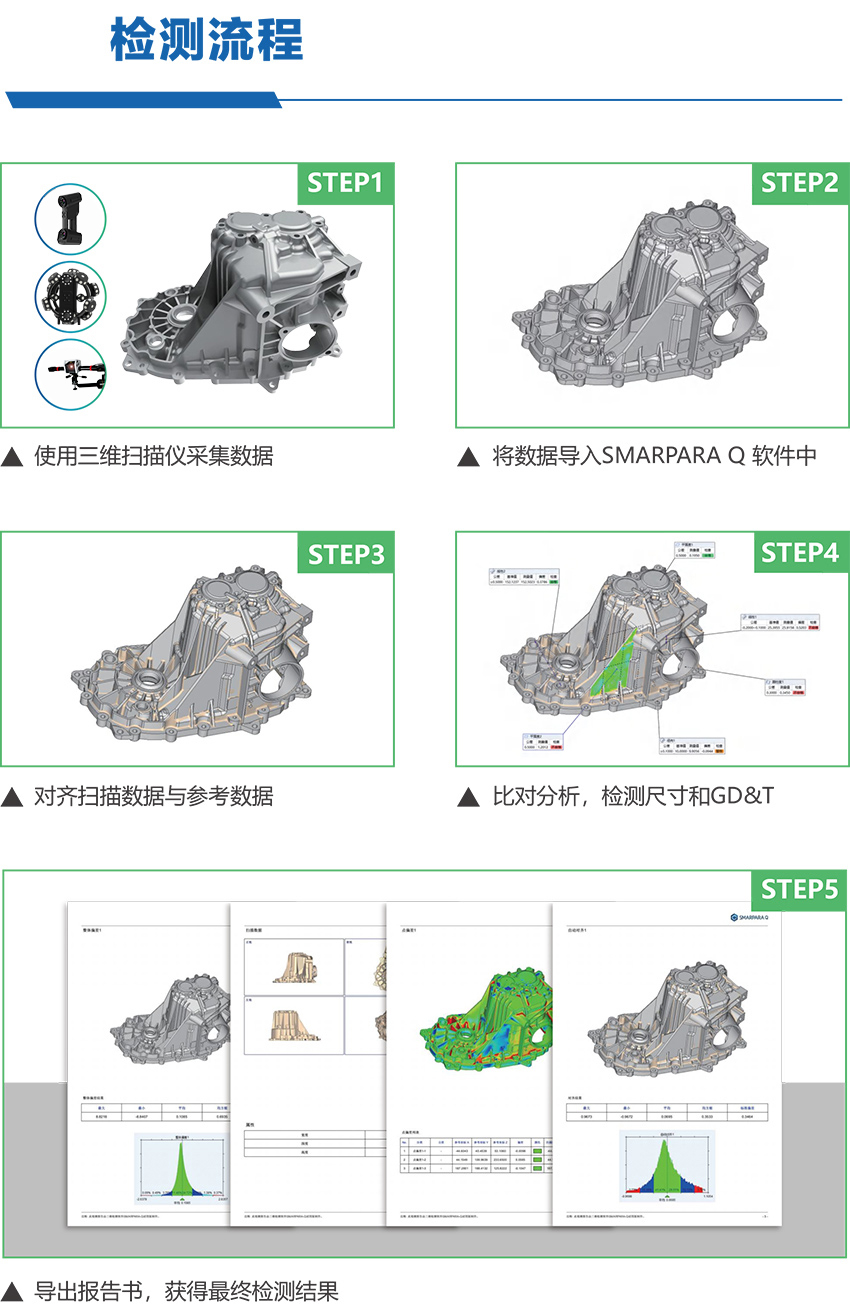

SMARPARA Q is a powerful computer-aided 3D quality control software that embeds a large number of standardized tools required by the industry. Based on the underlying high-precision algorithm and simple workflow, SMARPARA Q performs accurate and fast inspection tasks for parts with complex shapes and numerous features, providing high-precision, high-efficiency, high-reliability, and high-performance products for all-round quality control. Intelligent industrial-grade professional detection software tools.